We have free online training. You can come to STYLECNC for training in factory. We can also assign technician for door-to-door training with some charge.

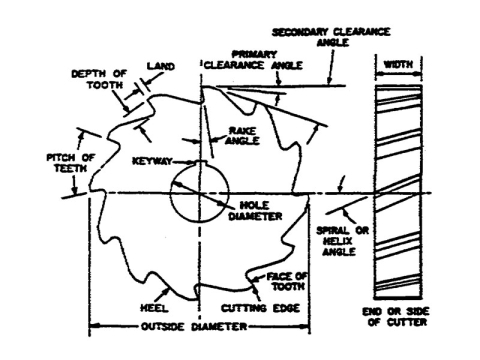

1. User Manual.

We provide document instructions for CNC machine installation, operation and debugging steps with pictures and texts.

2. Staff training.

Prepare training plans and make training handouts. After you purchase STYLECNC CNC machine, we can provide systematic training for users.

3. Telephone support.

After we receive a user's technical support request or fault report, we will immediately contact the user by phone and guide the user to solve the problem.

4. Remote connection service.

After the customer authorizes, the technical support personnel can enter the customer's system through a remote connection to help the customer solve the problem. It can be remotely connected to the customer's system to make programming adjustments on the customer's system, so as to ensure that the system produces the maximum benefit for the user.

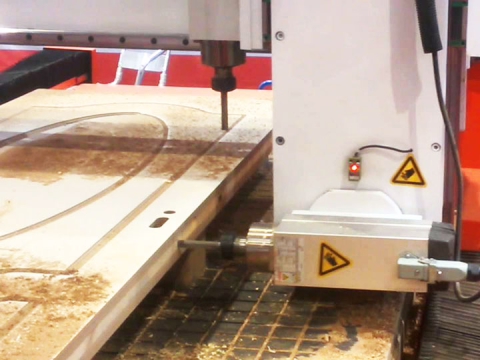

5. On-site service.

Under the authorization of the customer, enter the customer's software management system, regularly check the system operation status, and predict the possible problems of the CNC machine in the future; if the engineer needs to understand the judgment and solve the problem on the spot, our company will arrange the engineer as soon as possible at the fastest speed rush to the scene.

6. Regularly visit customers.

After the user purchases the CNC machine, arrange after-sales engineers to visit the customer regularly (online or on-site visits). On the one hand, prevent failures, and on the other hand, respond to various problems in a timely manner. You can also ask the user Some experiences or suggestions during the process can be used as suggestions for CNC machine optimization in the future.

7. Establish a dedicated emergency response team.

To ensure that when emergencies occur, technical personnel can be called quickly, emergency technical plans are formulated immediately, and problems are solved first.