The VMC1160 has been running smoothly since I bought it, performing multiple operations in one setup. This vertical machining center is extremely convenient and efficient for my engine parts business, improving productivity while ensuring accuracy. I have to give it five stars.

Industrial CNC Vertical Machining Center for Every Need

The industrial CNC vertical machining center is top-of-the-line for optimizing your automated manufacturing of precision metal parts and molds to maximize productivity, enabling quality-oriented production of high-quality components. The VMC1160 can easily handle everything from aircraft turbine blades to automobile engine blocks, as well as complex 3D molds in precision manufacturing.

- Brand - STYLECNC

- Model - VMC1160

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 1200mm x 600mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

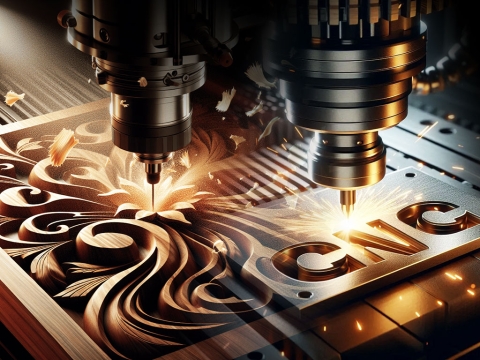

The industrial CNC vertical machining center (VMC) comes with a spindle axis set perpendicular to the worktable, making it easy to handle precision 2D sheet metal parts and complex 3D housing-shaped parts, as well as intricate metal molds.

The industrial vertical CNC machining center works with a variety of capabilities, including milling, boring, drilling, tapping, and threading.

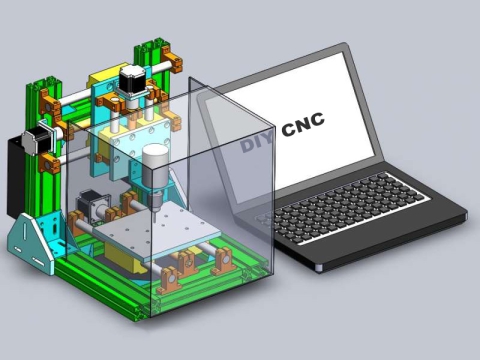

The industrial CNC vertical machining center requires at least three axes with two-axis linkage to function properly, and typically works with three axes with three-axis linkage, while some high-end models require a fourth or fifth axis for 3D machining.

The industrial vertical CNC machining center comes with X, Y, and Z axes as standard. 4th-axis and 5th-axis are optional for multi-angle and multi-directional machining. The VMC1160 utilizes a CNC controller for automated metal fabrication, featuring a compact structure, high speed and high precision, making it ideal for manufacturing a wide range of metal parts, molds, dies, and components. The VMC1160 is the preferred choice for industrial manufacturers, offering a perfect balance of speed and power to significantly boost your productivity.

Features

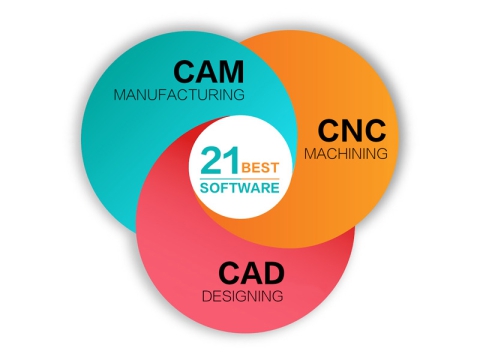

• CNC controller software options are available for GSK, Siemens, FANUC, Mitsubishi, KND and Syntec. The most user-friendly control is better than ever, faster, smarter, more powerful, and ready to help you create almost anything.

• Dual-layer worktable structure - Excellent vibration damping performance and balanced internal stress effectively prevent deformation.

• STYLECNC offers a 24-pocket high-speed arm-type tool magazine that can hold 24 tools, enabling quick tool changes in just 2 seconds and minimizing downtime.

• Anti-collision alarm system - Tool wear monitoring, tool breakage detection, tool life prediction alarm, and automatic shutdown control functions.

• Purpose-built spindles are custom-engineered for power, precision, and durability.

• Thermally symmetrical spindle-box design - Cross-reinforcing rib structure effectively suppresses thermal deformation.

• X/Y axis linear guides and Z axis rigid guides are optional to meet individual customization needs.

• Intelligent integrated control cabinet - Long service life, high stability, low failure rate, resistance to arc interference, and convenient maintenance.

• Multi-axis machining is optional, 3, 4, or 5 axis . . . bring it on. All STYLECNC vertical machining centers are available with 5-axis capability. Just add a rotary to build a powerful 5-axis CNC machine for a fraction of the price.

Specifications

| Model | VMC1160 | VMC1370 | VMC1580 | VMC1890 | |

|---|---|---|---|---|---|

| Travel | X/Y/Z axis travel | 1100×600×600mm | 1300×700×700mm | 1500×800×700mm | 1800×900×800mm |

| Spindle nose to worktable distance | 120-720mm | 110-810mm | 155-855mm | 150-950mm | |

| Spindle center to column guideway distance | 600mm | 750mm | 850mm | 965mm | |

| Worktable | Worktable(L×W) | 1200×600mm | 1300×700mm | 1500×800mm | 1800×900mm |

| Worktable maximum load | 800kgs | 1300kgs | 1500kgs | 2000kgs | |

| T-slot (number-width-distance) | 5-18-100 | 5-18-110 | 5-22-140 | 5-22-165 | |

| Spindle | Spindle motor power | 11KW | 15KW | 18.5KW | 22KW |

| Spindle speed | 8000rpm | 6000rpm | 6000rpm | 6000rpm | |

| Spindle taper | BT40/Φ150 | BT50/Φ155 | BT50/Φ155 | BT50/Φ190 | |

| Spindle transmission type | Belt drive | Belt drive | Belt drive | Belt drive | |

| Tool Magazine | Tool capacity | 24pcs | 24pcs | 24pcs | 24pcs |

| Tools change way | Arm type | Arm type | Arm type | Arm type | |

| Tool change time | 2.5s | 2.5s | 2.5s | 2.5s | |

| Accuracy | Positioning accuracy | 0.008mm | 0.008mm | 0.008mm | 0.008mm |

| Repeated positioning accuracy | 0.005mm | 0.005mm | 0.005mm | 0.005mm | |

| Feed Speed | X/Y/Z-axis rapid feed | 36/36/24m/min | 24/24/24m/min | 24/24/18m/min | 24/24/18m/min |

| Maximum cutting feed speed | 10000mm/min | 5000mm/min | 5000mm/min | 5000mm/min | |

| Others | Overall dimensions (L×W×H) | 3400×2480×2960mm | 3870×3160×2920mm | 4260×3360×3120mm | 4460×3360×3220mm |

| Weight | 7300kgs | 10000kgs | 13000kgs | 15000kgs | |

| 3-Axis VMC | Movement | Tool moves along X (left/right), Y (front/back), and Z (up/down) axes for flat surfaces. | |||

| Capabilities | Simpler programming than multi-axis machines for many standard jobs, making it ideal for prototyping, tooling, fixture making, and producing simple 2D/2.5D parts, especially good at drilling, tapping, milling cavities, and making molds. | ||||

| 4-Axis VMC | Movement | Adds a rotary 4th axis (A or B) to the standard X, Y, Z. | |||

| Capabilities | Rotates the workpiece 360 degrees, allowing machining of holes, slots, or features on cylindrical parts in a single setup, making it ideal for helical shafts, drill bits, parts with indexed features. | ||||

| 5-Axis VMC | Movement | Adds two rotational axes (A, B, and C) to X, Y, Z. | |||

| Capabilities | The tool or workpiece can move in any direction and at any angle, machining any surface of a 3D object, such as curved or oblique surfaces in one setup, making it ideal for complex impellers, molds, dies, engines, and artificial bones. | ||||

Applications

The VMC1160 industrial CNC vertical machining center is capable of milling, drilling, tapping, boring, and reaming a vast range of materials, from hard metals such as steel (carbon, alloy, stainless), titanium, and cast iron, to soft metals such as aluminum, copper, and brass.

The VMC1160 vertical CNC machining center is primarily used in a wide variety of industries such as aerospace (turbine blades, supports, and structural components requiring extremely high precision), automotive manufacturing (engine parts, transmission parts, and parts with complex curved surfaces), medical devices (surgical instruments, implants, and prostheses), tool & die (molds, jigs, and dies with complex features that can be made in a single setup), electronics (housing, connectors, and small, high-precision parts), heavy equipment (pump parts, heavy machinery parts, and industrial parts), and general manufacturing (prototyping, custom parts, and small to medium-volume production).

Projects

Pros

• The workpiece clamping and positioning are convenient with vertical machining centers.

• The cooling conditions are easily established, allowing cutting fluid to reach the tool and machined surface directly.

• The tool movement trajectory is easy to observe, making program debugging, inspection, and measurement convenient. Problems can be detected promptly, allowing for downtime for troubleshooting or modification.

• Compared to comparable horizontal machining centers, vertical machining centers feature a simpler structure, smaller footprint, and lower cost.

• The three coordinate axes are aligned with the Cartesian coordinate system, providing a clear and intuitive view consistent with the drawing, facilitating chip removal and falloff, and preventing scratches on the machined surface.

• The repeatability accuracy reaches 0.005 mm.

• The testing standards are twice as high as industry standards.

Cons

The VMC1160 vertical CNC milling machine is limited by the column height and tool changer, which restricts the height of the workpiece. When machining cavities or concave surfaces, chip removal is difficult, potentially damaging the tool and the machined surface, hindering the machining process. This limits its ability to machine only a limited range of box-shaped workpieces.