We bought the SI-IV for making furniture from willow and oak wood sheets. This CNC router works so excellently. Within 8 hours, it can finish 100 slice sheets. Fast speed and high precision. Highly recommended.

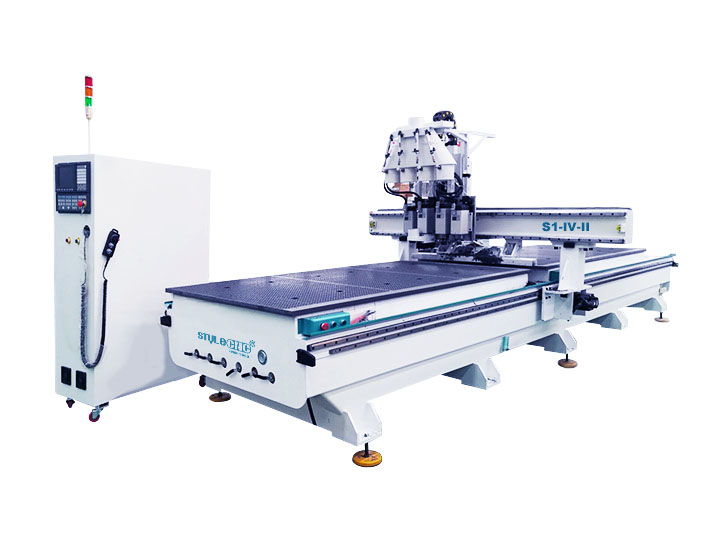

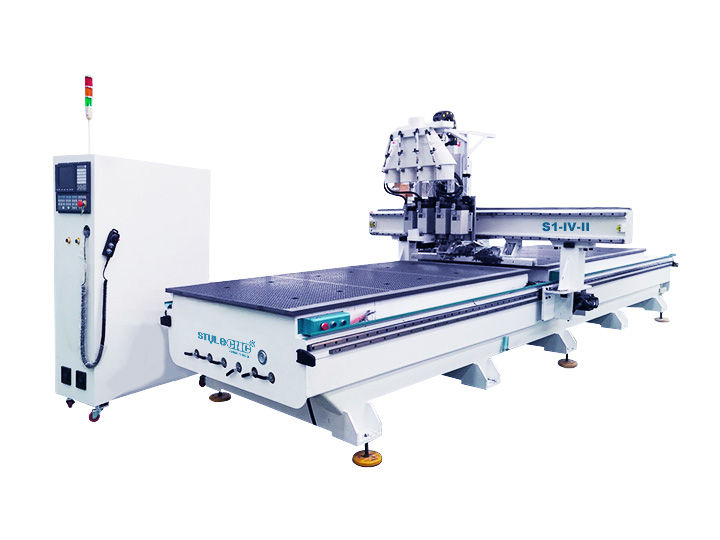

Wood Door Making CNC Router Machine with Dual Table

Wood door making CNC router machine is equipped with dual tables for wood door making, cabinet door making, home door making, and room door making, the wood door making machine is mainly used for wood door mass production.

- Brand - STYLECNC

- Model - S1-IV-II

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What is a Dual Table CNC Router?

A dual table CNC router is a specialty tool used to increase woodworking production efficiency. Dual table CNC routers provide two distinct working surfaces, as opposed to single table typical CNC routers. As a result, while one table is being loaded or unloaded, the machine can work on another, cutting, engraving, or milling. As a result, production is increased through continuous operation with little downtime. For wood door manufacturers, this feature is highly beneficial because it significantly reduces waiting times and increases the overall output of the machine.

The dual table design ensures smoother workflow transitions, making it ideal for large-scale production where speed and efficiency are critical. In short, a dual table CNC router is a powerful tool for businesses looking to streamline production without sacrificing quality.

Features and Advantages of Wood Door Making CNC Router Machine

1. Double working tables for work exchange, which can improve working efficiency and production.

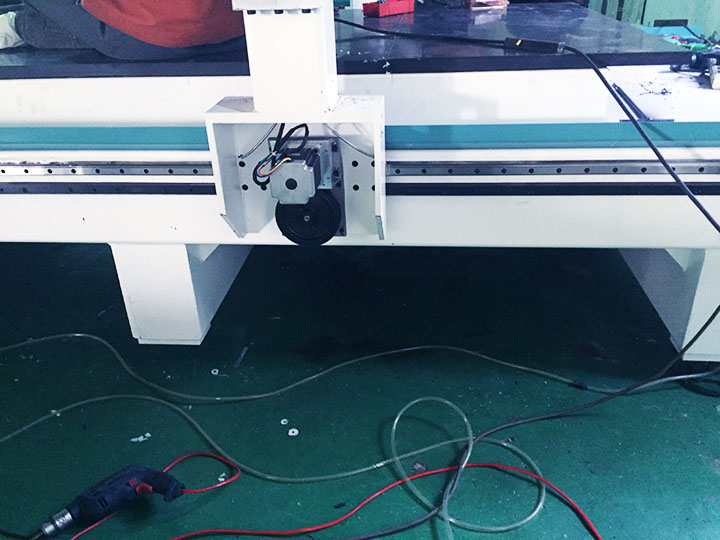

2. Linear rails on X, Y (the Y axis is controlled by two motors), and Z (Taiwan ball screw transmission) axis are used to guarantee high accuracy and stable performance and support heavy weight. The square sliding blocks have of good dust-proof effect. An automatic oil feeding and lubricating system makes regular maintenance very easy.

3. Superior high-power air-cooling spindle could keep working at low noise levels, safeguarding stability for long-time operation.

4. Break-point memory function enables the machine to continue the unfinished work after a work shift or accidents, such as tool breaking.

5. Compatible with many CAD/CAM software, such as Type3, Artcam, Castmate, Wentai, etc.

Applications of Wood Door-Making CNC Router Machine:

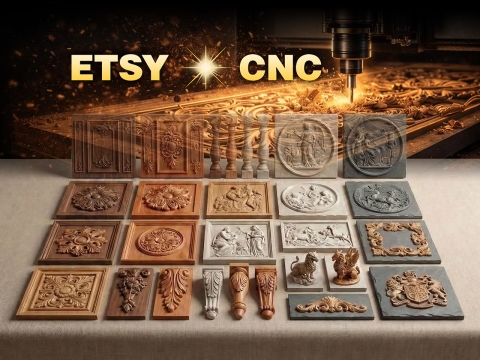

Wood door-making machine is widely used in the process of single lines, milling, 3D cutting, and engraving in the furniture processing industry, woodworking decoration, wood artwork, home decoration, and door manufacturing.

Technical Parameters of Wood Door Making CNC Router Machine

| Model | S1-IV-II |

| Working Area | 1300x2500x200mm |

| Table Size | 1450x2940mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| X,Y,Z Reposition Accuracy | ±0.03mm |

| Table Surface | Vacuum Table |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Power Consumption | 3.0Kw(Without Spindle) |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 2*4.5kw+2*3.5KW |

| Spindle Speed | 0-18000RPM |

| Drive Motors | Easy servo System |

| Working Voltage | AC380V/50/60Hz,3PH (Option: 220V)) |

| Command Language | G Code |

| Operating System | NC Studio control system |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| Collet | ER20 |

| X,Y Resolution | <0.03mm |

| Software Compatibility | Type3/UcancameV9 Software, (Option: Artcam Software) |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Packing Size | 3300X2100X2300mm |

| N.W. | 1600KG |

| G.W. | 1800KG |

Wood Door Making Machine Detail Pictures

Wood Door Making Machine Projects

Choosing the Right CNC Router for Wood Door Making

The right CNC router can significantly impact the quality and efficiency of your wood door production. Carefully consider the features that will best match your business needs for long-term success.

Table Size

The size of the router table determines the maximum door size you can work with. Larger tables allow you to handle standard and oversized wood panels with ease. This flexibility is essential for producing custom or intricate designs without requiring additional adjustments.

Spindle Power

The spindle power affects how effectively the machine can cut through thick or hard materials. Higher spindle power allows for faster and more accurate cutting, even on dense wood. This is especially useful for creating detailed or high-precision designs on wood doors.

Software Compatibility

Your CNC router needs to be compatible with popular design software like ArtCAM or AutoCAD. Having seamless integration with your design tools ensures a smooth workflow from design to execution. It also allows you to automate repetitive tasks, saving time and effort.

Durability and Build Quality

Look for CNC routers built with sturdy materials like steel or aluminum to ensure long-term use. A well-constructed machine will withstand heavy workloads and deliver consistent results. Opt for models with reliable warranties to protect your investment in case of technical issues.

Customer Support and Warranty

A strong support system is crucial when dealing with advanced machinery. Ensure the manufacturer offers reliable customer service and a comprehensive warranty. This will provide peace of mind, especially if you encounter technical difficulties or need replacement parts.

Maintenance and Durability of CNC Routers with Dual Tables

Maintaining your CNC router properly can increase its longevity and guarantee smooth performance. You can avoid expensive repairs and production delays by adhering to routine maintenance procedures.

Regular Cleaning

The CNC router's performance can be impacted by the accumulation of dust, debris, and wood shavings. Preventing wear and tear can be achieved by routinely cleaning the spindle, rails, and other essential components. Maintaining a clean equipment lowers the likelihood of unplanned malfunctions and guarantees smooth functioning.

Lubrication of Moving Parts

A good lubricant is necessary for the moving parts of CNC routers, which include bearings and rails. By reducing wear and friction, lubricant application prolongs machine life. To prevent component damage, develop the practice of routinely checking the lubricant levels.

Spindle and Cooling System Maintenance

One of the most important components of the router is the spindle, which needs to be inspected frequently. A potential problem is overheating, so make sure the cooling system is operating effectively. Proper spindle maintenance will minimize costly downtime and keep your machine running at peak performance.

Electrical and Software Checks

Check the electrical components of the router on a regular basis for wear and damage. Make sure the machine's software is up to date to prevent incompatibilities. Software and an electrical system that are kept up to date guarantee smoother, error-free operations.

Following Manufacturer's Guidelines

To maintain the machine's best condition, always adhere to the manufacturer's maintenance recommendations. Neglecting weight limitations or overloading the machine might cause long-term harm. The router will operate more reliably and last longer if prescribed procedures are followed.