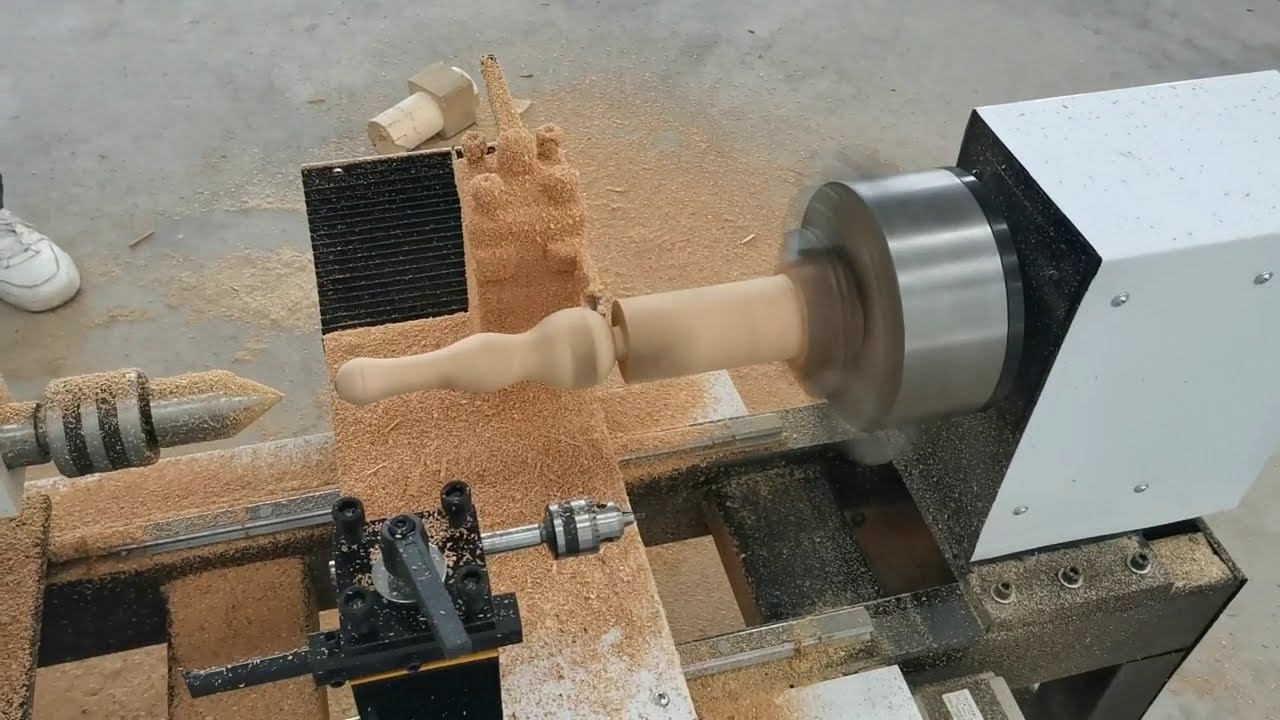

Automatic Lathe Machine for Spindle Turning Blanks

This video shows an automatic wood lathe machine turning spindle blanks to cylinders such as stairway balusters, Roman columns, baseball bats, newel posts.

Small CNC lathe machine is a popular wood turning power tools for woodworking, which is mainly designed for craftsman in home shop with hobbyists.

The small CNC lathe machine is a conjoined structure of the spindle box and the feed box. It uses high-speed steel or carbide tools to process hardwood, softwood, and glued wood, and can complete rough and fine woodturning processes such as outer circle, inner hole, end face, tapered surface, grooving, and cutting. Realize fully automated operation, one-time finished products, greatly improve work efficiency, CNC wood lathe machines are mainly used to process wooden crafts, wood beads, wood arts, wooden bowls, wood pens, wood cups, pen holders, and other workpieces with rotating surfaces.

Forthose who engaged in woodworking, the accuracy and intelligence of CNC lathe machines and their high work efficiency are important reasons why they choose to use wood lathes. Many large and medium-sized woodworking enterprises that have begun to take shape have begun to use CNC lathe machines to replace ordinary lathe machines for woodworking.

Compared with traditional lathe machines, what are the advantages of CNC wood lathe machines?

1. Automated operation mode

Compared with traditional lathe machines, the degree of automation of CNC wood machine tools has been greatly improved. Numerical control wood lathes do not require workers to operate the equipment all the time, but only use a programming language to compile the content of the drawings into the computer of the numerical control lathe before processing. The computer will actively analyze and direct the operation of the equipment through the central processing unit. Such a CNC machine tool is a great relief for manpower and greatly improves the accuracy of handover.

2. One machine is more productive, it is imperative to improve work efficiency

The traditional lathe intelligently processes one product at a time during processing, while the dual-axis and double-cutter CNC wood lathe machines can process two or more identical products at the same time. Simple operation, convenient drawing, simple and easy to understand, one-key conversion of product styles, no professional knowledge personnel can operate it with a little training. In addition, the fully automated CNC woodworking lathe can operate 2-3 units at the same time by one person, which greatly improves the processing efficiency, saves labor and money, and brings good economic benefits.

3. Simple operation, high precision and high cost performance

Compared with traditional woodworking lathe machines, CNC woodworking lathes have the advantages of simple operation and high precision. And now there are more and more CNC lathe machines and manufacturers on the market. Choosing a cost-effective CNC lathe machine for woodworking is particularly important for hobbyists and industrial manufacturing.

This video shows an automatic wood lathe machine turning spindle blanks to cylinders such as stairway balusters, Roman columns, baseball bats, newel posts.

All in one CNC wood turning and carving lathe machine can make the complex shape of rotary wood projects or semi-finished wood products.

Except for wood, STL1530-S CNC lathe machine can also be used for Nylon rod and acrylic with double blades for turning, 4.5KW spindle for grooving & carving.