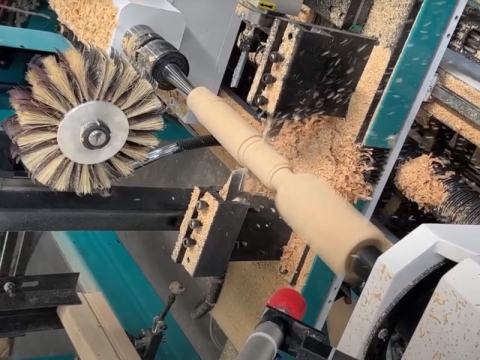

High Performance CNC Wood Lathe for Stair Baluster Turning

Are you looking for a self-service woodworking tool to personalize stair balusters? Here is a CNC wood lathe that can help you automate stair railing turning.

How to make multiple woodworking projects at once on one lathe machine? You will understand how does an automatic multitasking wood lathe turn double projects at the same time in this video.

Dual spindle CNC wood lathe is an automatic multitasking lathe that can make two same woodworking projects at one time.

It comes with single-blade, double-blade, or four-blade, and is ideal for manufacturers of stairs, furniture accessories, table legs and chair legs.

The dual spindle automatic wood lathe has a special feeding and centering device, which is convenient for feeding, has a detachable heel tool holder, and can process thin columns. The stable bed and efficient CNC machining program ensure the surface finish of your projects. The dual spindle lathe can be used for automatic batch processing, and the amount of cutting can be broken down.

You can set up and down processing in the system, and set different processing depths. The reciprocating blade return function is generally used for vases with ball heads or very large drops. During the shape turning process, a certain part is processed back and forth, and other parts are formed at one time. This function shortens the processing time to the greatest extent.

Precise Configuration

The dual spindle CNC lathe machine adopts frequency conversion speed regulation, imported ball screws, linear slide rails, stepping motors and other high-efficiency and precise electromechanical components to greatly improve the accuracy and efficiency of the machine tool.

Efficient Production

The dual spindle CNC lathe machine adopts a dual-axis design. When producing wood products of general specifications, two projects can be processed at the same time to double the efficiency.

Humanized Design

The automatic centering system is used in the clamping of square wood blanks. Before use, adjust the height of the feeder according to the size of the square wood, push it to the left position before clamping, and use the V-shaped notch to position the square wood. One-time positioning, convenient and quick, push it to the right after clamping for safe turning.

Humanized Operation

In order to meet the needs of different users, we have designed two systems: CNC controller and PLC controller, and users can choose arbitrarily when purchasing.

CNC Controller

It adopts industrial intelligent all-in-one control system, does not require manual input, supports U disk operation, avoids computer virus interference, controls turning speed, features with high reliability and high efficiency, and effectively guarantees processing accuracy when working around the clock. At the same time, it is easy to learn, and customers can quickly and flexibly master the use of the equipment.

PLC Controller

It is equipped with high-performance compact PLC control system, English menu display, simple programming, no special training is required, the numerical control programming is changed to directly input the processing size, the system can store more than 100 sets of processing data, one input can be used at any time, suitable for users who are not good at computer operation.

Operating System

DSP control handle, easy to use and easy to learn.

Auxiliary Parts

Welded and cast thickened steel plate, small vibration, no deformation, high stability.

Power Supply Parts

The frequency conversion speed regulation system is adopted, which can solve the problem of wood chatter by adjusting the rotation speed.

Transmission Parts

Top brand linear guide rail (square rail helical gear, ball screw), high precision and stable operation.

Controller Parts

Adopt a mature CNC controller, which works stably and is easy to install and debug. Use the international standard CNC language - G code. Support a variety of software, support technical function expansion.

Moving Parts

Driven by high-precision stepping motors to ensure accurate processing dimensions, using top brand guide rails, combined with ball screw drive, strong environmental adaptability, and not afraid of dust. Ensure machining accuracy. Frequency conversion speed regulation, automatic spindle operation, high degree of machining automation.

Bed Frame Parts

Casting molding, stable structure, high-frequency quenching and grinding imported linear square rail, small vibration to ensure high-precision machining.

Spindle Parts

Double spindles are used to turn two woodworking projects at once with high efficiency.

Are you looking for a self-service woodworking tool to personalize stair balusters? Here is a CNC wood lathe that can help you automate stair railing turning.

This video shows an automatic wood lathe machine turning spindle blanks to cylinders such as stairway balusters, Roman columns, baseball bats, newel posts.

STL1516 CNC wood lathe machine with double axis and four blades, which can turn two pieces of wood projects at one time.