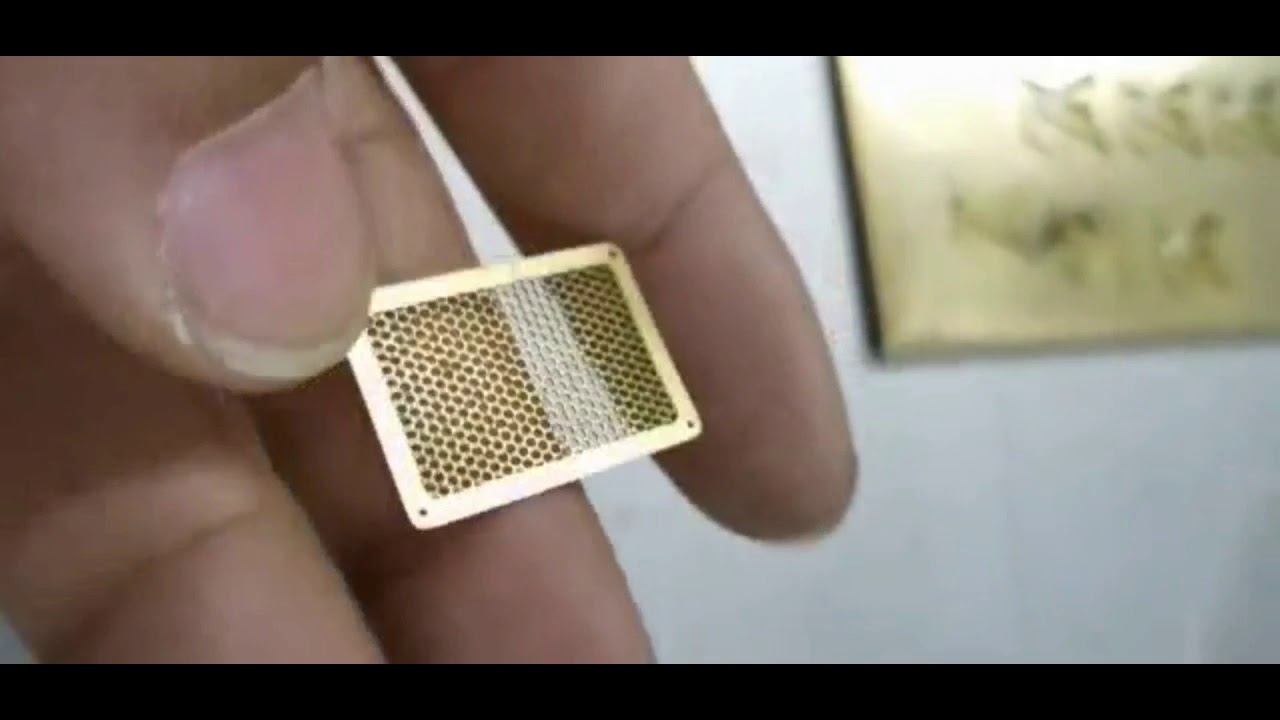

20W MOPA Fiber Laser Marking IMEI on iPhone Back Cover

iPhone back cover IMEI laser marking need to use 20W MOPA fiber laser marking machine. Other laser source will easily lead to deformation of the material.

Review the test video to cut high reflective metals with IPG fiber laser cutter. Buy the right metal laser cutter for brass, copper, silver, gold, aluminum, and bronze, aluminum, and other reflective metals of infrared light in their solid state.

Reflective metal is a type of metal material that can reflect the wavelength directed to it, including copper, brass and bronze. Aluminum, silver and gold have the highest reflectivity, with the latter reflecting about 95% of visible light.

In the work of laser cutting, some users often encounter metals with high reflectivity, such as copper and aluminum. The cutting of these metals requires special attention. Due to their reflective properties, if the cutting parameters are adjusted incorrectly or the surface is not polished, the laser lens may be damaged.

The working principle of the CO2 laser cutter is to make the heat of the laser beam be fully absorbed by the material, and the reflective properties of the metal will cause the laser beam to be repelled. In this case, the reverse laser beam will enter through the head of the lens and mirror system of the laser cutting machine, causing damage to the machine.

In order to prevent the reflection of the laser beam, several measures need to be taken. For example, the reflective metal is covered with a coating that absorbs the laser beam. This cutting method will not affect the quality and accuracy of the cutting, and the laser cutter is not damaged.

In addition to the above treatments, most modern laser cutting machines are also equipped with a self-protection system. In the case of laser beam reflection, the system will shut down the laser cutter machine to prevent damage to the lens. The whole system works according to the principle of radiation measurement, that is, it is monitored during cutting. Moreover, the advancement of technology has developed a laser cutting system that can resist this situation, which is a fiber laser, especially IPG laser source from Germany.

Fiber laser technology is one of the latest metal cutting technologies, and its performance is far superior to carbon dioxide lasers.

Fiber lasers use fibers that guide the laser beam instead of using a complicated mirror system. Using a fiber laser cutting machine instead of carbon dioxide to cut reflective metal materials is the fastest and most cost-effective alternative.

iPhone back cover IMEI laser marking need to use 20W MOPA fiber laser marking machine. Other laser source will easily lead to deformation of the material.

Leather shoes laser cutting machine with double heads is used for engraving and cutting leather, fabric, textile, acrylic, rubber, plastic and other nonmetals.

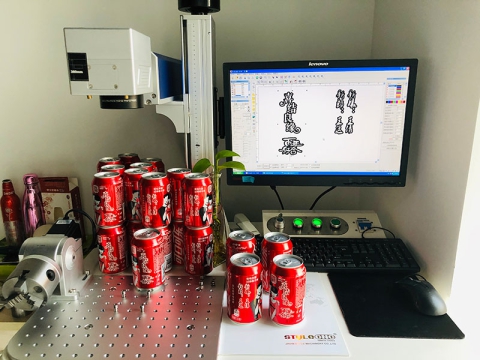

This is a video of fiber laser engraving machine for coca-cola aluminum cans cover engraving as custom wedding gifts for Cherry from STYLECNC.