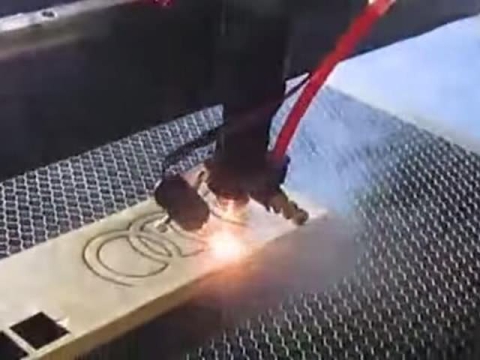

12mm Wood Laser Cutter STJ1390

12mm wood laser cutter STJ1390 can be equipped with different laser powers for different wood cutting.

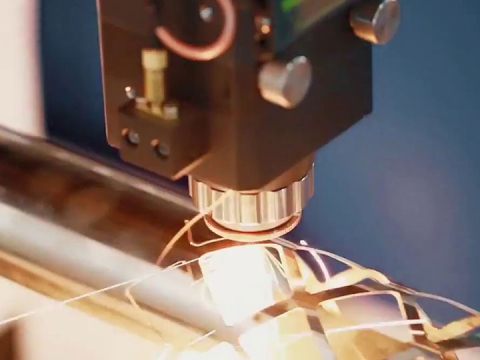

Need a high precision laser cutter for metal fabrication? You will understand what is the laser machine you want from this video of fiber laser cutting sheet metal.

Fiber laser cutting machine is a device that has a laser to convert electrical energy into light energy, and its electro-optical conversion rate is 30%. Then, the high-energy light is concentrated on the surface of the plate through the cutting head, and the part of the plate that is exposed to the light is instantly vaporized, and the numerical control program is used to move the cutting effect. In essence, laser processing is thermal cutting, which has less deformation than traditional shears, punching machines and other machines.

Compared with CO2 laser cutting machine, fiber laser cutting machine has great advantages and has gradually become a popular metal cutting equipment in the metal fabrication market.

The fiber laser cutting machine can cut metal materials such as carbon steel, stainless steel, aluminum alloy, brass, copper, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy and so on.

Fiber laser metal cutting machine has high speed, high precision, high efficiency and stable performance. It is really fast, stable, accurate and trustworthy.

1. Economical

In addition to a part of the electricity and consumable costs, the fiber laser cutting machine has no other expenses, and only one person is required to operate it. Whether it is mass production or small batch production, it can be satisfied. If compared with the traditional punching machine, the cost of mold opening is also required, and the product is single. If the product shape needs to be changed, the mold needs to be reopened. However, the flexibility of the laser cutting machine solves this problem well, and it can be easily processed by inputting the drawing into the program.

2. Practicality

The fiber laser metal cutter cuts the workpiece with high precision. Compared with traditional processing tools, it eliminates the secondary grinding process, reduces the workload of personnel and shortens the delivery time. In addition, the processing materials and thicknesses are very wide. It is no problem to cut stainless steel, copper aluminum, carbon steel and aluminum alloy.

3. Efficiency

Efficiency determines economic benefits. The cutting speed of fiber laser metal cutting machine can reach 100 meters per minute, which means that the efficiency of completing a small workpiece is only a few seconds. Compared with traditional equipment such as plasma or wire cutting, the cutting speed of laser is faster. too much.

1. Advanced cutting technology

The cutting principle of this new type of fiber laser cutting machine is a high-performance laser cutter. During the cutting process, the laser emits countless high-performance, high-energy laser rays. The huge energy produced by these laser rays , The cut surface can be vaporized instantly, so that the very hard interface can be easily removed. At present, this process is still the most advanced cutting process, no other cutting process can surpass it, and this cutting process is very fast in the cutting process, it can easily cut very thick steel plates in an instant, and cut The accuracy of the cutting is also very accurate, and the cutting cross section accuracy can reach a few millimeters, which can fully meet some high-demand cutting needs.

2. The cutting performance is very stable

This kind of high precision laser cutter uses an extremely stable world-class laser in the cutting process. The service life of this kind of laser will be as long as several years, and in the process of use, except for human factors, almost no production Any system failure, so even if this laser cutting machine is under long-term working pressure, it will not produce any vibration or other adverse effects.

3. The mechanical operation process is very convenient

In our process of using fiber laser metal cutter, all information and energy transmission are transmitted through optical fiber. The biggest advantage of transmission in this way is that it saves a lot of manpower and material resources. Any light path leakage will occur. And without any optical path adjustment before using the equipment, energy can be easily transferred to the laser.

12mm wood laser cutter STJ1390 can be equipped with different laser powers for different wood cutting.

Fiber laser tube cutter adopts 1000W, 2000W or 3000W fiber laser source for cutting metal tubes and sheet metals with different thickness.

You will understand how does 100W laser cutting machine STJ1390 cut cast clear acrylic sheet and produce a smooth glossy cut edge in this video.