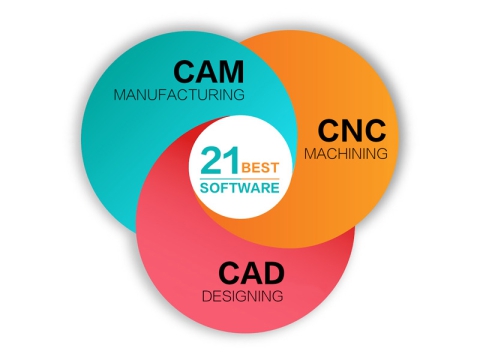

If you're shopping for a new or used CNC machine in today's marketplace. This list explores the easy-to-flow steps a buyer would take to purchase a CNC machine. Let's begin.

Step 1. Consult: we will recommend the most suitable CNC machines to you after being informed by your requirements.

Step 2. Quotation: We will supply you with our detail quotation according to our consulted machines with the best quality and price.

Step 3. Process Evaluation: Both sides carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

Step 4. Placing Order: If you have no doubts, we will send you the PI (Proforma Invoice), and then we will sign a sales contract.

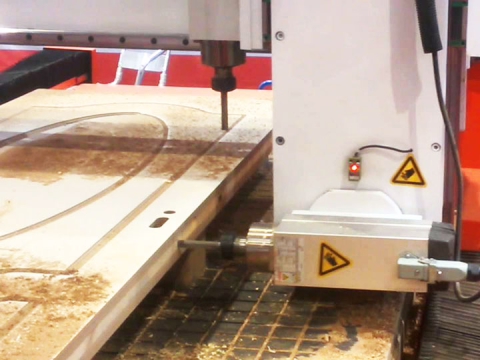

Step 5. Production: We will arrange the production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the buyer during the production.

Step 6. Inspection: The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before out of factory.

Step 7. Delivery: We will arrange the delivery as the terms in the contract after the confirmation by the buyer.

Step 8. Custom Clearance: We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 9. Support and Service: We will offer professional technical support and service by Phone, Email, Skype, WhatsApp around the clock.