This vertical mill is fantastic! After six months of use, it's still running like new, fast, precise, and powerful. I'm extremely satisfied with the high performance of this CNC machine and the prompt after-sales service.

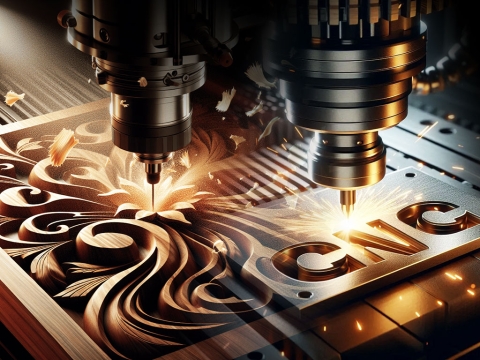

Small CNC Vertical Milling Machine for Metal Fabrication

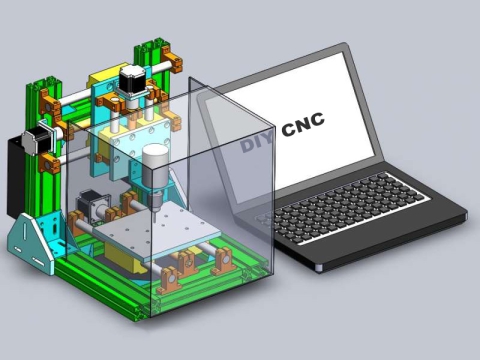

A mini CNC vertical milling machine (VMC650) is a small yet powerful machining center used in schools, home stores, startups, or as an affordable entry-level CNC mill for beginners to manufacture a variety of precision metal parts and molds.

- Brand - STYLECNC

- Model - VMC650

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 800mm x 500mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

The VMC650 CNC vertical milling machine is a small-sized computer-controlled automated machining center with its spindle axis set perpendicular to the worktable. It is ideal for precision machining of sheet metal, disc-shaped parts, molds, complex shell-like parts.

The VMC650 CNC vertical machining center (VMC) is small but complete, loaded with full-size features. It is a multifunctional CNC machine tool capable of milling, boring, drilling, tapping, and threading.

A CNC vertical milling machines requires at least three axes with two-axis linkage to function properly, and typically works with three axes with three-axis linkage, while some high-end models require a fourth or fifth axis for 3D machining.

The VMC650 is a three-axis vertical CNC milling machine, coming with X, Y, and Z axes as standard, with an optional fourth axis for rotary machining of cylindrical workpieces. It utilizes a CNC controller for automated metal fabrication, featuring a compact structure, small footprint, high precision, and high speed, making it ideal for small metal parts manufacturing and precision mold making. The VMC650 is small yet powerful, a perfect combination of speed and power, which can take a bite out of cycle times. Compared to full-size vertical machining centers, the price is relatively affordable.

Features

• Key components such as the machine bed, column, and spindle box are all made using resin sand (closed-firing) casting, ensuring structural stability and long-lasting quality. The castings have undergone finite element analysis, with optimized structural strength and reinforcing ribs, resulting in high mechanical rigidity. The casting structure employs a one-piece molding process, a box-type structure, and is machined in a single setup on a large five-sided machining center. This gives the machine tool high rigidity, high strength, and excellent geometric accuracy, guaranteeing long-term stability and high precision. Furthermore, to prevent deformation after machining, the castings undergo thorough annealing to eliminate internal stress.

• The base is wide, and the column adopts a triangular box-type structure with a heavy-duty full support design, ensuring robust structural strength and heavy-load capacity during machining.

• The symmetrical design balances the weight on both sides of the column, maintaining stable machine tool accuracy.

• The spindle box is reinforced with reinforcing ribs, and the contact length between the spindle box and column has been optimized to provide stable support for the spindle.

• Three-axis positioning accuracy meets ISO-230-2 standard.

• The X, Y, and Z axes utilize linear roller guides, with a table load capacity of up to 500KG. These guides feature high rigidity, low noise, and low friction, enabling rapid displacement and optimal roundness accuracy.

• The servo motors for the X, Y, and Z axes are directly connected via flexible couplings and high-precision ball screws, reducing intermediate links and achieving backlash-free transmission, flexible feed, precise positioning, and high transmission accuracy.

• The Z-axis servo motor has an automatic locking function; it automatically locks the motor shaft in the event of a power outage, preventing rotation and providing safety protection.

• The spindle assembly uses professional high-precision, high-rigidity spindle components. P4-grade spindle-specific bearings enhance the spindle's lifespan and reliability. The spindle offers stepless speed regulation within its speed range, and the motor's built-in encoder control enables spindle orientation and rigid tapping functions.

• 4th-axis and 5th-axis are optional for multi-angle and multi-directional machining.

Specifications

| Model | VMC650 | |

|---|---|---|

| Travel | X/Y/Z axis travel | 600×500×500mm |

| Spindle nose to worktable distance | 120-620mm | |

| Spindle center to column guideway distance | 550mm | |

| Worktable | Table size (L×W) | 800×500mm |

| Worktable maximum load | 400kgs | |

| T-slot (number-width-distance) | 5-18-90 | |

| Spindle | Spindle motor power | 5.5KW |

| Spindle speed | 8000rpm | |

| Spindle taper | BT40/Φ120 | |

| Spindle transmission type | Belt drive | |

| Tool Magazine | Tool capacity | 16pcs |

| Tools change way | Arm type | |

| Tool change time | 2.5s | |

| Accuracy | Positioning accuracy | 0.008mm |

| Repeated positioning accuracy | 0.005mm | |

| Feed Speed | X/Y/Z-axis rapid feed | 24/24/24m/min |

| Maximum cutting feed speed | 12000mm/min | |

| Others | Overall dimensions (L×W×H) | 2300×2160×2200mm |

| Weight | 3800kgs | |

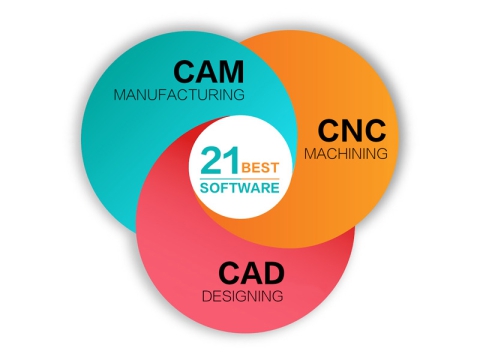

| 3-Axis VMC | Movement | Tool moves along X (left/right), Y (front/back), and Z (up/down) axes for flat surfaces. |

| Capabilities | Simpler programming than multi-axis machines for many standard jobs, making it ideal for prototyping, tooling, fixture making, and producing simple 2D/2.5D parts, especially good at drilling, tapping, milling cavities, and making molds. | |

| 4-Axis VMC | Movement | Adds a rotary 4th axis (A or B) to the standard X, Y, Z. |

| Capabilities | Rotates the workpiece 360 degrees, allowing machining of holes, slots, or features on cylindrical parts in a single setup, making it ideal for helical shafts, drill bits, parts with indexed features. | |

| 5-Axis VMC | Movement | Adds two rotational axes (A, B, and C) to X, Y, Z. |

| Capabilities | The tool or workpiece can move in any direction and at any angle, machining any surface of a 3D object, such as curved or oblique surfaces in one setup, making it ideal for complex impellers, molds, dies, engines, and artificial bones. | |

Applications

The VMC650 vertical mill is primarily used for small-size machining of most planes, cavities, contours, and precision holes in mold making, automobiles, aerospace, electronics, and medical devices.

Projects

Pros

• The testing standards are twice as high as industry standards.

• The repeatability accuracy reaches 0.005 mm.

• The workpiece clamping and positioning are convenient with vertical machining centers.

• The tool movement trajectory is easy to observe, making program debugging, inspection, and measurement convenient. Problems can be detected promptly, allowing for downtime for troubleshooting or modification.

• The cooling conditions are easily established, allowing cutting fluid to reach the tool and machined surface directly.

• The three coordinate axes are aligned with the Cartesian coordinate system, providing a clear and intuitive view consistent with the drawing, facilitating chip removal and falloff, and preventing scratches on the machined surface.

• Compared to comparable horizontal machining centers, vertical machining centers feature a simpler structure, smaller footprint, and lower cost.

• Its compact size allows it to fit into most freight elevators.

Cons

The VMC650 vertical CNC milling machine is limited by the column height and tool changer, which restricts the height of the workpiece. It also suffers from a small worktable, making it incapable of handling larger parts and molds. When machining cavities or concave surfaces, chip removal is difficult, potentially damaging the tool and the machined surface, hindering the machining process. This limits its ability to machine only a limited range of box-shaped workpieces.