Laser cutting technology has advanced the cutting methods and precision ever more than before. The cutting is done using a concentrated laser beam at high temperature. This technology is welcomed in almost every industry. The versatility of the machines makes laser cutting more popular and outstanding.

It features the usability of a wide range of materials to shape, carve, or engrave. But in particular, plastics require more attention while making a project with them. Yes, Laser cutting polycarbonate is possible. You just need to know how to find the best suit for your project and fix the machine properly with accurate parameters.

Today, we are going to discuss the versatility of laser cutting technology and how to use it most efficiently. We are also going to break down the fact if laser cutting polycarbonate is possible or not, and if possible how to do that. Let's dive into the mastery of manufacturing cutting tools.

What is laser cutting?

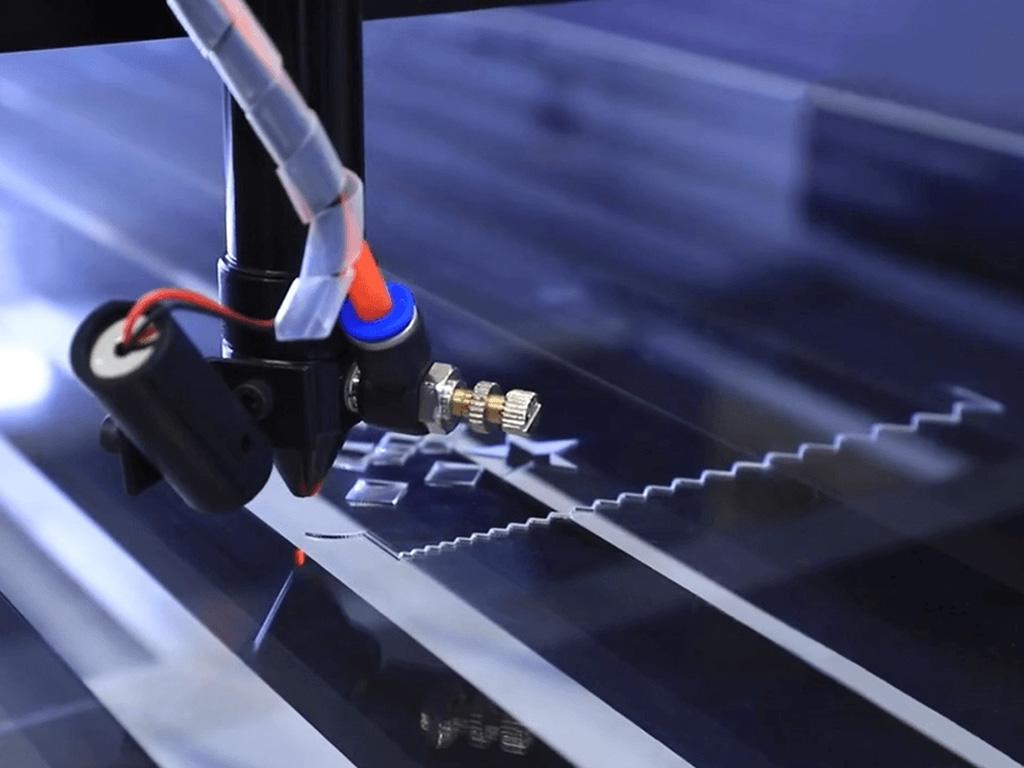

Unlike traditional cutting and sawing methods laser cutting introduces a high-temperature laser beam-cutting tool that offers the most precise and efficient manufacturing outcome. The laser is usually focused and controlled through CNC router machines.

There are two common types of lasers used for the job.

1. Carbon Dioxide (CO2) lasers and

2. Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers.

The CO2 laser is suitable for non-metals like wood, acrylic, and fabric. On the other hand, Nd: YAG lasers are used for cutting metals and are capable of higher power outputs.

Laser cutting is used on a wide range of materials (metals and non-metals). Currently, laser cutting is available for cutting, engraving, or shaping steel, aluminum, copper, wood, acrylic, plastic, leather, fabric, rubber, etc.

Is it safe to laser-cut polycarbonate?

Laser cutting polycarbonate can be done with caution since many plastics are not suitable to cut using heat. It is important to know what kind of plastic you are going to cut.

The thickness and material density also impact the cutting. All plastics are not recommended to be cut using a laser. Specifically talking about polycarbonate, they cut very poorly and often discolor and catch fire. Usually, this material is found as sheets. For some specific reason laser cutting polycarbonate is not recommended for all purposes.

Therefore, due to the lesser effectiveness of laser on polycarbonate, it is considered a poor choice to use laser cut. But if necessary and with better thickness laser cutting polycarbonate is possible. Let’s see what are the potential difficulties to face while laser cutting polycarbonate.

Challenges of laser cutting polycarbonate

Polycarbonate tends not to work out with the laser cutting method. Yet you can get your job done only by following precautions and proper steps. But first, let’s find out the various challenges to face while laser cutting.

✔ Generation of hazardous fume: High high-powered laser beam can generate toxic gases like carbon monoxide and hydrogen cyanide. In the absence of proper ventilation, this can cause severe health conditions.

✔ Material sensitivity to heat: Polycarbonate is sensitive to heat. Extra heat can cause this material to melt, burn, or undesirable surface.

✔ Potential for thermal stress and warping: Thermal stress is common with overheating laser beams. This often leads to discoloration and distortion of material. It also affects dimensional accuracy and fit of the final product.

✔ Difficulty achieving clean edges: Achieving clean and smooth edges is challenging while laser cutting polycarbonate. Initially, the edges are prone to melt and tend to regain their shape. Meanwhile, the edge loses smoothness and shape.

✔ Effects of additives and coatings: Polycarbonate sheets with additives and coatings come with more challenges. When the material is heated these additives and coatings produce additional toxic gases and bi-products.

Besides, the risk of surface damage, the complexity of parameters optimization, and regulatory compliance and safety standards are a few factors that face additional challenges.

The best way to cut polycarbonate

Unlike laser cutting, there are more effective cutting methods for polycarbonate. The best way to cut polycarbonate depends on several factors such as thickness, desired precision, etc. We have gathered a few ways considered most effective in cutting polycarbonate. Let’s find out which works best for you.

B. CNC Router

C. Table Saw

D. Jigsaw

E. Score and Snap Method and

F. Waterjet Cutting

They are proven useful with fewer challenges and better precision to a certain extent.

Safety Precautions

Plastic materials are not eco-friendly materials for our environment. Yet versatile composition makes them useful in many industries. Cutting polycarbonate using laser cutting technology requires special safety precautions.

The safety precautions need to be improvised actively. Here are a few key safety considerations,

✔ Proper ventilation is a must to remove toxic gases and contaminants. Use an exhaust system to remove fumes effectively.

✔ Use the suitable equipment only to maximize the smoothness and accuracy of the shape.

✔ Try to use polycarbonate sheets specifically made to laser cut. Take necessary steps if additives or coatings are available on the sheet.

✔ Wear an appropriate PPE set at work. Make sure your PPE comes with gloves, masks, and protective clothing.

✔ Fire safety is very important in laser-cutting polycarbonate. Keep a fire extinguisher nearby. Keep the flammable objects at a distance.

✔ Dispose of plastic waste properly.

Tips to cut polycarbonate efficiently

Cutting polycarbonate can be difficult in certain work environments. However, a few tips can come in handy. Try them out to get better results.

1. Select the right tools

Choose the appropriate cutting tools based on the thickness of the sheet. Use a table saw on thin sheets and jigsaw for curved or irregular cuts.

2. Use proper cutting techniques

Fix the sheet properly on the bed to avoid chipping or cracking. When using table saw use clamps to secure the sheet. Using a jigsaw? Move it slowly and steadily.

3. Optimize cutting parameters

Considering thickness adjust the cutting speed, feed rate, and blade speed. Try different settings to find the optimal balance.

4. Minimize heat buildup

Avoid excessive friction using sharp-edge tools. This will reduce the overheating issue. Apply cutting lubricants or cooling agents for more effective results.

5. Protective measures

Wear proper PPE set and use a dust mask.

6. Clean up

Remove debris and wastage immediately. Use sandpaper to bring smooth and clean edges.

How to clean discolored polycarbonate after laser cutting

Laser-cutting polycarbonate usually results in discoloring. Not following the proper usage instructions results in this discoloration problem!

Now, what are you going to do once the product comes with discoloration? We have given you a few ideas that may improve the final result. You can follow them step by step to get rid of this unwanted condition.

⇲ Allow the material to cool

⇲ Gently remove surface debris

⇲ Prepare a cleaning solution

⇲ Apply the cleaning solution

⇲ Rinse thoroughly

⇲ Buff with polishing compound

⇲ Check and repeat if necessary

You can apply a protectant additionally to prevent future discoloration.

Fiber laser cutting polycarbonate

Fiber laser cutting is more popular among consumers for cutting polycarbonate. A suitable polycarbonate sheet can ensure an efficient cutting result. A proper parameter setup is also responsible to avoid overheating and prepare a smooth cutting action.

Follow the thermal precautions given at the top of the article and you are all good to go.

Post-processing is also a significant task to finally achieve a proper production. Follow the safety considerations available for laser cutting polycarbonate.

Laser cutting polycarbonate VS acrylic

Polycarbonate and acrylic are two different materials. In terms of applying similar cutting methods, both can result in contrasting. Let’s take a look at the similarities and dissimilarities of laser cutting polycarbonate and acrylic.

| Laser Cutting Polycarbonate | Laser Cutting Acrylic |

|---|---|

| Polycarbonate is a thermoplastic polymer known for its strength, durability, and impact resistance. It is transparent and commonly used as a substitute for glass due to its lightweight and shatterproof properties. | Acrylic, also known as PMMA (polymethyl methacrylate) or Plexiglas, is a transparent thermoplastic that resembles glass but is lighter and more impact-resistant. It is often used as a cheaper alternative to glass in various applications. |

| Polycarbonate absorbs fiber laser wavelengths, making it suitable for cutting with fiber lasers. However, care must be taken to avoid excessive heat buildup and potential thermal damage to the material. | Acrylic is transparent to CO2 laser wavelengths, making it well-suited for cutting with CO2 lasers. CO2 lasers are commonly used for cutting acrylic due to their ability to produce clean, precise cuts with minimal heat-affected zones. |

| When laser cutting polycarbonate, it's essential to control heat buildup to prevent melting or charring of the material. Fiber lasers are typically used for cutting polycarbonate, and proper parameter optimization is crucial to achieve clean, precise cuts. | Acrylic cuts cleanly and efficiently with CO2 lasers, which are well-suited for cutting through the material without excessive heat buildup. CO2 lasers offer high precision and can produce intricate designs with smooth, polished edges. |

| Laser-cutting polycarbonate can sometimes result in rough or melted edges due to heat buildup during the cutting process. Proper parameter optimization and post-processing may be necessary to achieve smooth, clean edges. | CO2 lasers produce clean, polished edges when cutting acrylic, resulting in high-quality finished products with minimal post-processing required. Acrylic is well-suited for applications where optical clarity and edge quality are critical. |

| Polycarbonate is commonly used in applications requiring impact resistance and durability, such as safety shields, protective covers, and machine guards. Laser-cutting polycarbonate is suitable for creating custom shapes and designs in these applications. | Acrylic is widely used in signage, displays, lighting fixtures, and architectural applications due to its clarity, versatility, and ease of fabrication. Laser-cutting acrylic allows for precise cutting of intricate designs and letters for these applications. |