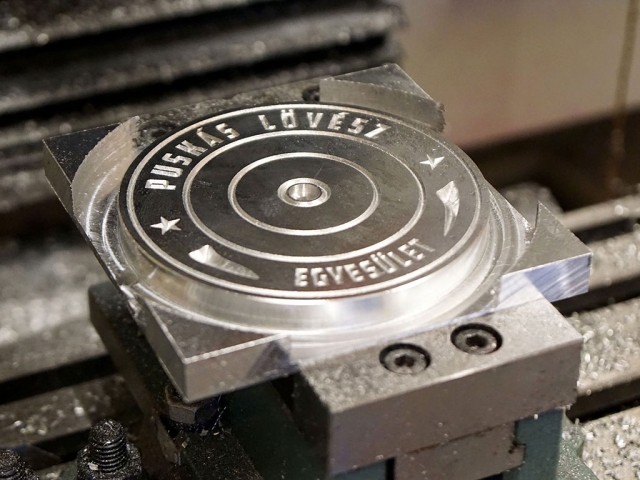

CNC Metal Engraving Machine Applications and Samples

CNC metal engraving machine is used for carving, milling and drilling compactly all types of materials such as steel, copper, aluminum, wood, stone, plastics.

Explore STYLECNC's picks of the popular CNC milling aluminum mold projects, from simple, one-off designs to complex molds requiring intricate surface finishes.

CNC milling machines can create various aluminum molds for a variety of industrial manufacturing processes, including designing custom molds for injection molding, vacuum forming, or die casting. The key steps include CAD design, selecting the appropriate tooling, setting the feeds and speeds for the aluminum, and programming the computer-controlled machine tool to ensure precision. You can use a CNC machine to make most popular aluminum molds, ranging from simple designs to complex 3D molds that require intricate surface treatments for industries such as automotive, aerospace, shipbuilding, and consumer products.

CNC milling machines can precisely cut and shape aluminum blocks into the desired mold design. The milling process begins with a 3D model design, which needs to be converted into a tool path that dictates the tool movement. The CNC milling machine removes material from the aluminum workpiece in a series of operations using specific cutting tools, such as end mills or ball drills, and adjusts feed rates and spindle speeds based on the material properties. The precision of CNC milling allows for complex designs, smooth surfaces, and tight tolerances that are essential to making high-quality molds.

Designed for a variety of applications, such as injection molding or die casting, CNC milling machines offer high precision and repeatability, making them ideal for producing the complex geometries and features required for manufacturing. The things to consider when using a CNC machine to mill aluminum molds include choosing the right milling tool, optimizing milling parameters, and ensuring that the cooling system is used to prevent overheating during machining.

The advantages of using CNC machines to mill aluminum molds include high precision and repeatability, which allows for complex designs and tight tolerances, and higher production speeds compared to traditional tools. However, disadvantages remain, including the higher initial cost of CNC machines and software, the machine deterioration, and the requirement for a skilled operator.

CNC metal engraving machine is used for carving, milling and drilling compactly all types of materials such as steel, copper, aluminum, wood, stone, plastics.

You will find a series of copper, brass milling projects & ideas by CNC milling machine, which will be the best reference to DIY or buy a CNC mill.

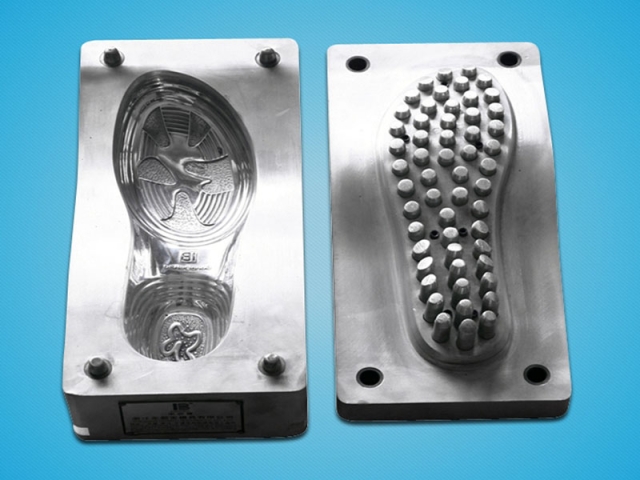

You will find all kinds of metal shoe mold making projects with CNC milling machine equipped with automatic tool changer for shoe mold making plans and ideas.