CNC Plasma Cutter for Square & Round Metal Tube Cutting

CNC plasma cutter with rotary device besides the plasma cutting table can cut sheet metals, square and round metal tubes to realize multi-functional cutting.

How to choose the right CNC plasma cutting machine for your own metal fabrication business is a problem that you have to face. Whether it's cutting quality, speed, thickness, table size, technical support and service, it's all things to consider.

What type of CNC plasma cutting machine is the best choice for your metal fabrication business? After all, the price of a piece of equipment is a bit expensive. If the choice is not good, it will not only waste money, but also affect the interests of the enterprise. How to choose a CNC plasma cutter? I believe this problem has long plagued machining manufacturers. It is necessary to choose CNC equipment with reasonable price and high cost performance, but also to meet their own processing needs and improve competitiveness, so many customers do not know how to make a a decision?

The first thing to consider is the cutting quality of the equipment. If the cutting quality of the equipment is not good, other conditions are useless. So how do you know its cutting quality? Of course, this is also very simple, that is, to visit the site to see the debugging and proofing of the equipment, the cutting speed, the thickness of the cut plate, and how the cut samples are. CNC plasma cutting systems are widely used in various manufacturing and processing industries such as automobiles, sheet metal processing, precision accessories decoration, advertising, and metal external processing.

When purchasing a CNC plasma kit, in addition to considering whether it can meet some basic elements such as cutting thickness and cutting plate, it is also necessary to comprehensively consider many factors such as the price & cost.

Meet Your Requirements

Such as the maximum size of the processed plate, the material, the thickness of the plate that can be cut, and the format that can be completed. All in all, the equipment should be selected according to the company's own processing technology needs, and the cutting machine that can properly meet the company's own processing level is the best choice.

Performance

The machine tool with fast cutting speed, high precision, high processing efficiency and good cutting effect is naturally our first choice for purchasing equipment.

Stability

How to complete customer orders with quality and quantity is the basis for purchasing an automatic plasma cutting tool with stable performance.

After Sales Service

In the process of using, it is inevitable to encounter some problems, so high-quality after-sales service is particularly important. Instead of choosing products with low prices but no perfect after-sales service, it is better to choose machinery and equipment with excellent performance, high stability and high-quality after-sales service.

There are a lot of messy CNC plasma cutters on the market, and the quality of various brands is uneven. How to choose a business with good performance, affordable price and good after-sales service is the difficulty. Just choose an expensive product but the after-sales technical support cannot keep up, and the user will only spend a lot of money but get little gain. It's just that the price is affordable but the quality of the equipment is not good, and the user wastes money and human resources. With fast processing speed, good after-sales service and low cost of use, this is definitely the most cost-effective CNC plasma cutting machine.

CNC plasma cutter with rotary device besides the plasma cutting table can cut sheet metals, square and round metal tubes to realize multi-functional cutting.

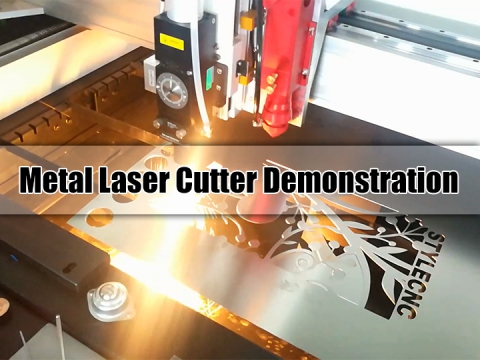

This is a sheet metal laser cutter demonstration video from STYLECNC, which provides all-round smart laser metal cutting solutions for metal fabrication plans.

This is a video of STP1325 4x8 CNC plasma table for 3mm aluminum sheet cutting with 60A Huayuan power supply, which is suitable for most sheet metal cutting.