Jeden z moich znajomych polecił mi STYLECNC, powiedział mi, że używa ich routera CNC, a maszyna działa dobrze przez 2 lata. Postanowiłem więc wypróbować ST6060F. Jestem bardzo zadowolony z zakupu tej maszyny od nich. Bez rozczarowania i jestem pod wrażeniem jego doskonałej wydajności.

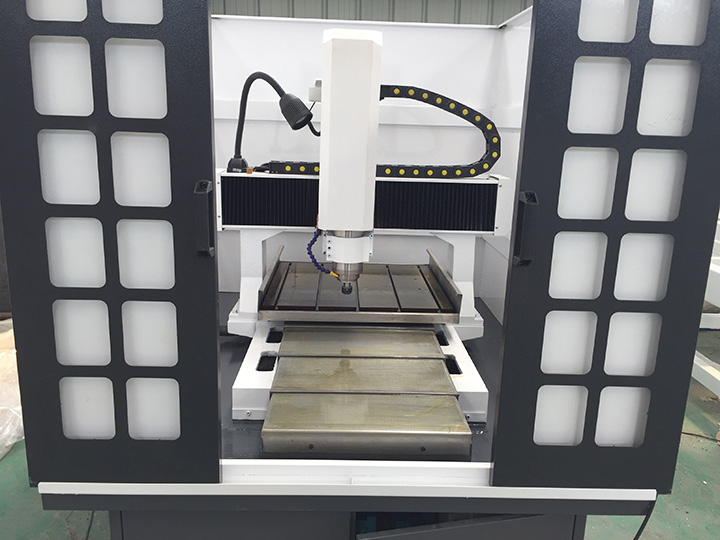

2025 Top Rated CNC Mold Making Machine for Sale

2025 top rated CNC mold making machine is a high-precision automatic molding machine, which is budget-friendly and easy to use for both beginners and professionals in metal mold shaping and forming. Now the affordable CNC molding machine for sale at cost price.

- Brand - STYLECNC

- Model - ST6060F

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 600mm x 600mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

A CNC mold making machine is a computer numeric controlled (CNC) milling tool designed for precise 2D/3D machining of various molds used in injection molding or casting. Computer-controlled mold making machines are also known as CNC molding machines, which automate the milling, cutting, shaping, and finishing of mold components with high accuracy and repeatability for creating complex shapes and designs with different materials, such as metals, woods, plastics, and composites.

CNC Mold Making Machine Features & Advantages

• Cooling system: Mist cooling system for spindle, cooling workpieces with oil in the tank, or atomization liquid through or spray nozzle.

• Quality assurance: For each device before leaving the factory, we will test the cue with a laser interferometer.

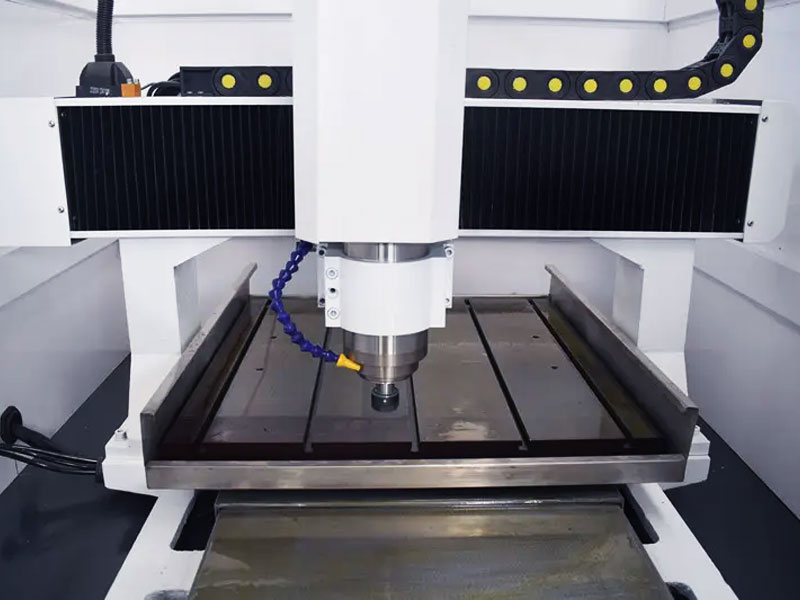

• Gantry structure: Whole cast-iron structure, steady structure, high rigidity, precision 0.01mm. The double column is the whole part, greatly increasing machine rigidity.

• The machine adopts a high-speed water cooling variable frequency motor, big torque, strong cutting, high-frequency,long-lifetime, and can be a long-time continuous working.

• Servo motor and drives: from Japan with high precision and long life.

• HIWIN linear guide: made in Taiwan, used for linear reciprocating stadium.

• Three axes all use German ball screws and Taiwan linear orbits to make sure accuracy and reposition precision.

• Functional and easy-to-operate control system made by Taiwan SYNTEC with high performance and competitive price.

• Table movement to keep stable and high precision.

• Enclosed work space ensures safe and contamination-free work.

• The mold-making machine is the product of the combination of numerical control technology and the engraving and milling process. It is a kind of multi-functional CNC machine. Similar to the ordinary numerical control machine, our metal engraving machine price realizes the carving, and the milling processing automation through that numerical control system controls the engraving and milling machine movement according to the processing procedure code.

• Stable and rigid structure: With the gantry type bed and table are one, it is not only good rigidity but also no installation error for both. Processing precision will not be affected even if being used for a long time.

• The mold-making machine is a kind of fully enclosed design, it adopts an external circulating cutting oil processing way. The machine body is fully cast with a stable structure and great weight-bearing ability.

• The mold-making machine is equipped with an accurate bidirectional ball screw of a famous brand, Taiwan square rail, and accurate bearing with strong rigidity and high dynamic accuracy. It is also equipped with a Japan YASKAWA AC servo motor with high accuracy and high power making the amplitude smaller and three-axis more stable.

Technical Parameters of CNC Mold Making Machine

| Model | ST4040F | ST6060F |

| Table Size | 400mm×400mm | 600mm×600mm |

| X/Y/Z Axis Movement | 550mm×450×200mm | 600mm×600mm×200mm |

| XYZ movement Accuracy | ±0.01/300mm | ±0.01/300mm |

| XYZ Repetition Accuracy | 0.005mm | 0.005mm |

| Feeding Height | 200mm | Max 300mm |

| Gantry Width | 740mm | 820mm |

| Max Loading Weight | 300kg | 350kg |

| Pressure Deformation of Working Table | <0.02mm(300kg) | <0.02mm(300kg) |

| Spindle Power | 2.2KW(Optional 5.5KW) | 3.2KW(Optional 5.5KW) |

| Tool holder | ER20 | ER25 |

| Spindle rotate speed | 24000rpm | 24000rpm |

| Max movement speed | 15m/min | 12m/min |

| Total power | 7.5KW | 13.5KW |

| Motor | Yaskawa Servo Motor | Yaskawa Servo Motor |

| Power supply | 380V ± 10%50Hz | 380V ± 10%50Hz |

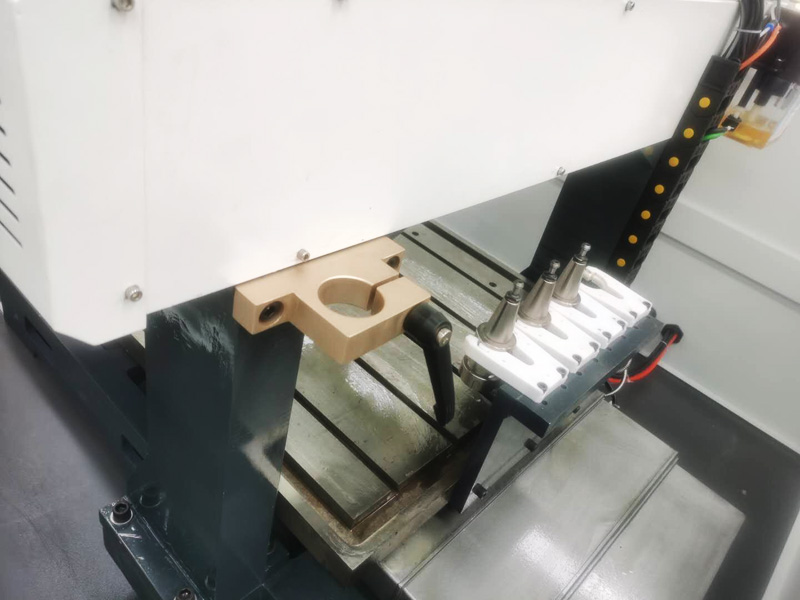

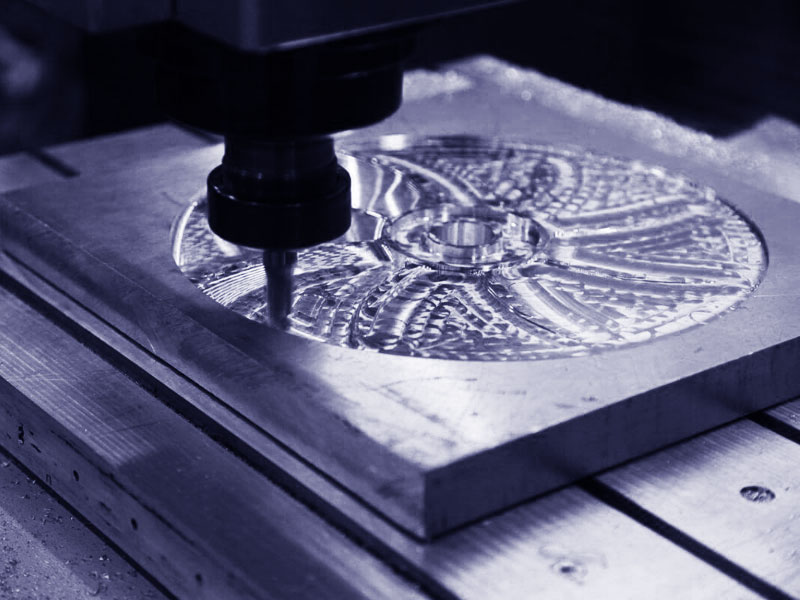

CNC Mold Making Machine Applications

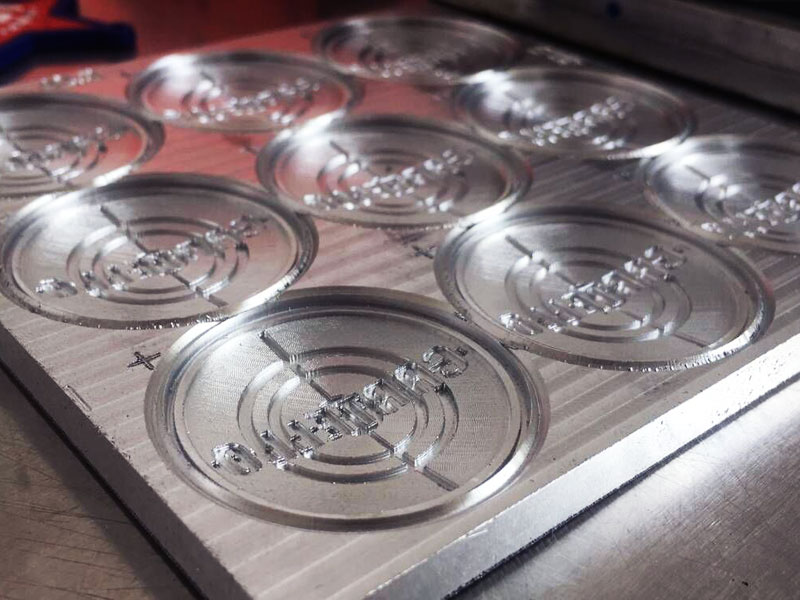

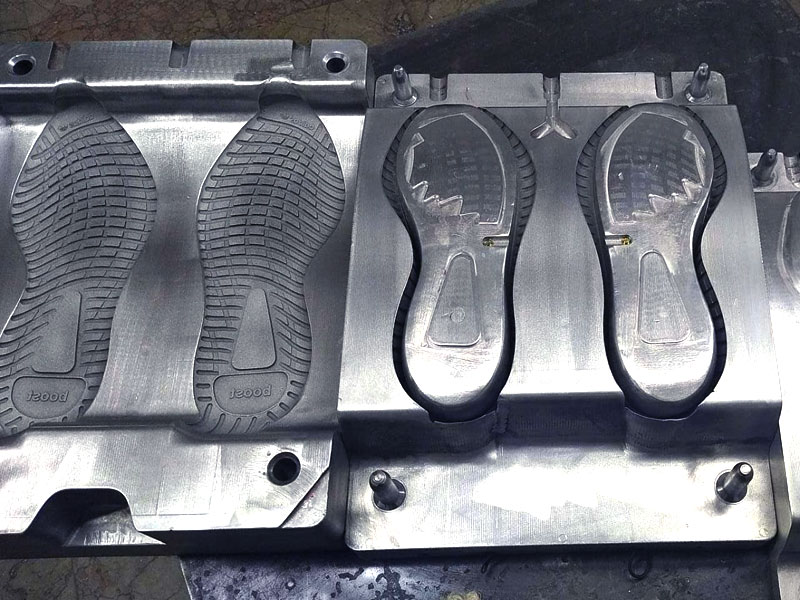

CNC mold-making machine is used for carving, milling, cutting, and drilling most materials, including copper, aluminum, steel, iron, brass, wood, foam, and plastics. It is widely used in injection mold, automotive, ironware mold, shoe mold, drop mold, metal molds, clock parts, copper electrodes, zinc electrodes, metal electrodes, metal crafts, metal arts, jewelry, jade, dental crown, and other molding industries. It is specially designed for batch machining molds, watches, eyeglasses, panels, brands, badges, outside surface's sleeking, three-dimensional graphics, and, words, It’s easy for this molding machine to produce 2D or 3D relieves on various materials.

CNC Mold Making Machine Projects

CNC Mold Making Process

Why Invest in a CNC Mold Making Machine?

CNC Mold Making Machines is an intelligent alternative, as it will entirely reinvent the production in itself. The machine precision simply finds no parallel, be it in automotive, aero manufacturing, or consumer product categories. Their ability for higher complexity design reduces any probable human error and thereby manufactures each piece consistently.

Another positive aspect of CNC mold-making machines is that they are very efficient. They save time in production compared to traditional methods, hence enabling businesses to work within strict deadlines. Besides, their compatibility with various materials, such as metals and plastics, adds versatility for diverse applications.

With time, a CNC mold-making machine becomes very cost-effective. By saving on material waste and reducing labor costs, it offers long-term savings while increasing productivity. This is a very good investment that pays off in efficiency and profitability for any business willing to be at par and deliver quality.

Maintenance Tips for Long-Lasting CNC Mold-Making Machines

Good maintenance of a CNC mold-making machine allows it to serve for long periods and run at the highest capacity. A properly maintained machine serves to reduce downtimes, along with precision and efficiency in the production process. Here are the key maintenance tips that shall keep your CNC mold-making machines running:

• Regularly clean the machine to remove debris, dust, and leftover materials. Accumulated waste can affect the machine’s components and precision. Use appropriate tools and avoid harsh cleaning agents that may damage surfaces.

• Check moving parts, such as spindles, guides, and ball screws, for signs of wear and tear. Lubricate them regularly using the manufacturer-recommended oils to minimize friction and prevent overheating.

• Keep the cutting tools sharp and without any damage. The worn-out tools can lead to poor-quality molds and put extra stress on the machine. Replace all dull or broken tools to ensure accuracy.

• Regular calibration of the machine will keep it very accurate. This not only includes the checking of axis alignment but also ensures that all settings are according to the manufacturer's specifications.

• Look for damage or wear on wiring, connections, and electronic controls. Any problems with the electrical system must be resolved quickly to prevent stoppages and damage.

Develop a maintenance schedule based on the amount of use your machine gets, and follow recommendations for routine service provided by the manufacturer. In this way, servicing is done on time, helping to avoid breakdowns.