Nesting CNC Router for Living Room Furniture Making

This is a video of S5 automatic nesting CNC router machine with 9V+4H drill bank for customized living room furniture making with Italy HSD spindle.

New CNC router STM1325 is designed for our Bahrain customer, he uses it for carving and cutting wooden door, windows, cabinets, and more woodworking projects.

New CNC router 1325 woodworking machinery is used for wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows. voice box, game cabinets, computer tables, sewing machines table, instruments, insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds, etc.

What are advantages of CNC router 1325 woodworking machinery?

1. Lathe bed adopts strong welded steel tube to avoid distortion.

2. 3KW water cooling spindle with top brand and longer working life.

2. DSP controller, no need to connect to PC, easily operate and learn.

3. Transmission. X and Y axis: gear and rack transmission; Z axis: Taiwan TBI ball screw transmisson.

4. Guide rail for X, Y, and Z axis, TAIWAN HIWIN square rail.

5. Stepper motor and Leadshine drivers, high positioning accuracy, good reliability, save power consumption.

This is a video of S5 automatic nesting CNC router machine with 9V+4H drill bank for customized living room furniture making with Italy HSD spindle.

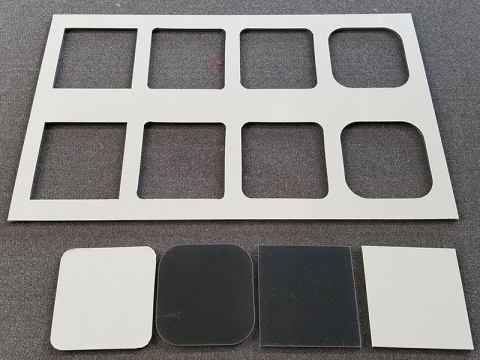

CNC tangential oscillating knife cutting machine is the best precision cutter for flexible polymers, foam, cardboard, fabric, plastic, and gasket materials.

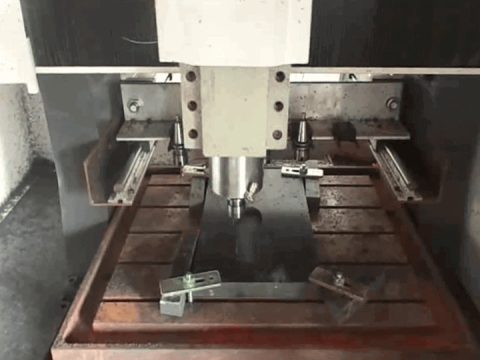

You will understand how does an ATC CNC milling machine for shoe mold making in this video, the CNC shoe mold making machine adopts tool changer with 4-6 tools.