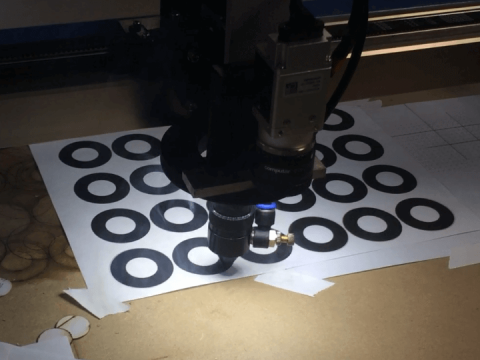

280W Mixed Laser Cutter Cutting 25mm Acrylic Signs

This video shows 280W mixed laser cutter for 25mm acrylic signs cutting, which can cut max 30mm acrylic sheet. And it can also cut some thin sheet metals.

This is a video on how does 1000W fiber laser tube cutting machine cut square tube of stainless steel with high speed, high precision and high quality.

Square tube laser cutting machine is used for cutting metal tubes of carbon steel, stainless steel, mild steel, aluminum, brass, alloy, the laser tube cutter is widely used in electronic components, automotive parts, cooling pipes, ventilation pipes, signs and other metal parts processing industry.

Square Tube Laser Cutting Machine Applications

Square tube laser cutting machines are used in sheet metal processing, metal processing, advertising production, kitchenware, automobiles, lamps, saw blades, electrical switch cabinets, metal crafts, textile machinery and other fields.

Square Tube Laser Cutting Machine Features

1. To satisfy users for rectangular processing, even the cutting of the oblique end face of the rectangular end can be operated and realized.

2. Support operations such as cutting square holes, waist-shaped holes and steel pipe cutting on rectangles.

3. Ability to cut variable-angle bevel surfaces, and all vertical and inclined intersections can be satisfied.

A class of products using advanced laser control technology and focus following technology. With a rectangular tube laser cutting machine, the cutting speed, edge effect and accuracy can be guaranteed.

Square Tube Laser Cutting Machine Advantages

1. High speed: The laser can cut several meters of pipe in one minute, and the pipe metal laser cutting machine is hundreds of times faster than the traditional manual method, which means that the laser processing is highly efficient.

2. Flexibility: The laser can flexibly process various shapes. The stainless steel pipe laser cutting machine allows designers to carry out complex designs, which is unimaginable under traditional processing methods.

3. Batch processing: The standard pipe length is 6 meters, and the traditional processing method requires very heavy clamping, and laser processing can easily complete the clamping and positioning of several meters long pipe, which makes batch processing possible.

This video shows 280W mixed laser cutter for 25mm acrylic signs cutting, which can cut max 30mm acrylic sheet. And it can also cut some thin sheet metals.

This video shows how does 1000W fiber laser cutting machine cut 1.5mm aluminum sheet. It can cut up to 3mm aluminum, for more thicker metal cutting.

STJ1610A-CCD CNC laser cutting machine with CCD camera is a professional cutter used for precision cuts of fabric, vinyl, paper, and more flexible materials.