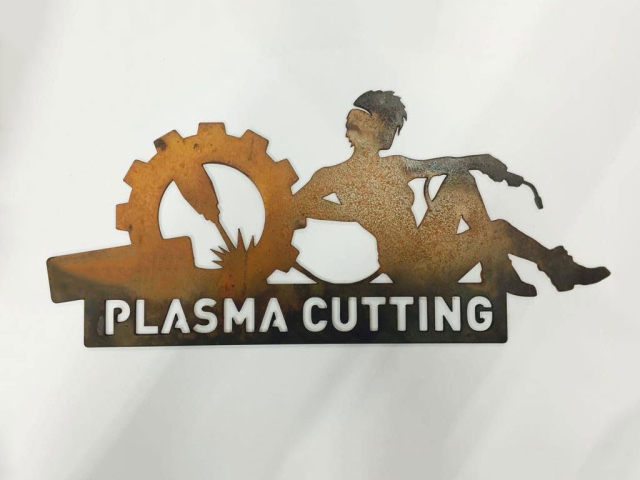

CNC Plasma Cutting Thin Metal Signs & Arts

Review the CNC plasma cutting thin metal signs & arts projects for advertising, decoration, hobbyists, small shop, home business, and commercial use.

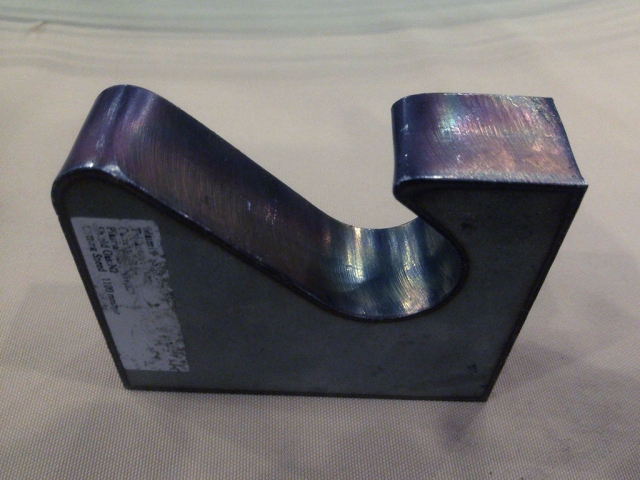

Plasma cutter is mainly used for cutting thick metal materials such as iron plates, aluminum sheets, galvanized sheets, stainless steels, and titanium plates.

Plasma cutter application industries: mechanical and electrical products, advertising signages, decoration, black smith gardens, automobile, ship building, electrical accessories, welding industry, etc.

Plasma cutter advantages:

1. Welded lathe bed of thick profiled steel, more solid and stable.

2. Perfect lathe table design, 10mm steel plates fixed on lathe table covered by cast sheath. The level difference of platform remains in 0-1.5mm.

3. Advanced material inclined discharging design.

4. CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc.

5. Support Fastcam, ARTCAM, Type3 software such as the standard G code path generated file can also be read by software conversion software such ad AUTOCAD generated DXF formats. U disk exchange control system processing files, easy to operate.

6. Plasma torch power supply and supporting all famous brands, a number of national patents by the manufacturers.

Review the CNC plasma cutting thin metal signs & arts projects for advertising, decoration, hobbyists, small shop, home business, and commercial use.

CNC plasma cutters are experts at cutting through a variety of thin and thick metals with ease and creating parts out of sheet metal, whether old or rusty.

You will find some applications and plans by CNC plasma cutting machine from STYLECNC, which will be a good reference to buy the best plasma CNC cutter.