Shipping fast, all well packed without damage. Very impressed from the moment we opened the packaging. All the parts appear to be well made and of high quality. Assembly was so easy that we had practice projects going in just a few minutes. Definitely recommend this CNC to anyone, including the beginners.

Budget-Friendly Hobby CNC Router Machine with 4x6 Table Kit

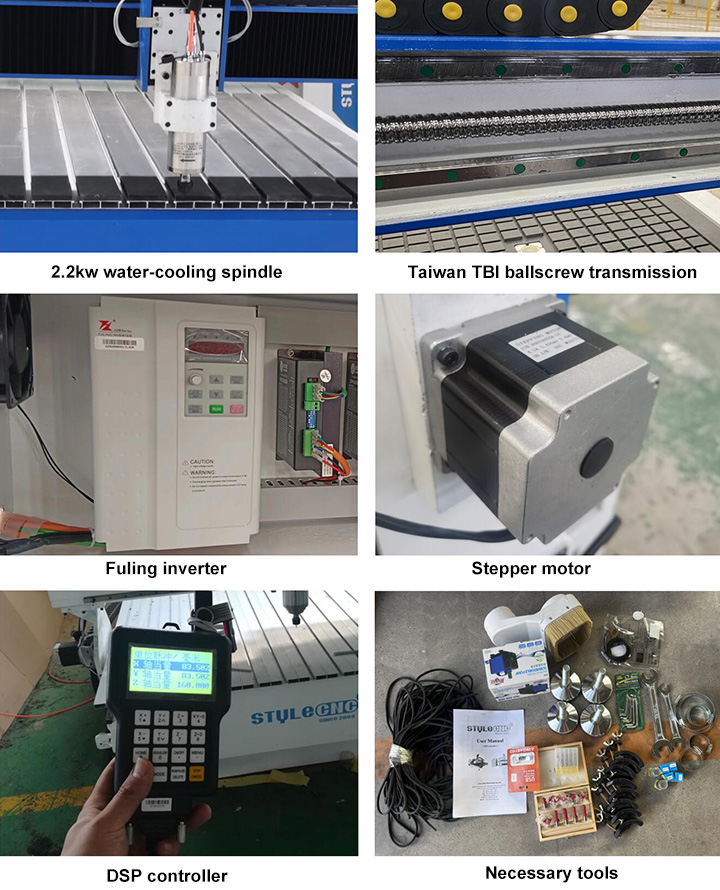

STG1218 CNC router machine is a budget-friendly hobby CNC kit for beginners with 4x6 table size, handheld DSP controller, stepper motor, water-cooled spindle.

- Brand - STYLECNC

- Model - STG1218

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 6' (48" x 72", 1200mm x 1800mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

CNC (Computer Numerical Control) router machines have advanced the approach of woodworking, engraving, or small-scale manufacturing for hobbyists and DIY enthusiasts. Hobby CNC routers are versatile, compact, and capable machines. They can perform well both at small workshops and houses.

These machines use computer software to precisely cut and control tools and manufacture intricately designed parts within a short period.

So, what about cheap hobby routers? Do they perform well? Let’s take a look at STYLECNC hobby routers that are cheap yet capable of doing most of your projects. Here you can find the information and reviews of our products along with the relevant information required to understand the machining process.

What is a hobby CNC router?

CNC routers are computer-controlled machines. These machines are operated through a software system usually provided with the model. The hobby CNC routers are specifically made for small-scale manufacturing, hobbyists, and DIY enthusiasts. Being compact they can perform very well with different projects within smaller space.

One of the appealing factors is that these machines despite being smaller in size compromise very little with their performance. Because of that they are widely used in small workshops and houses.

Hobby CNC routers come with various bed sizes. The most common pick is a 4x6 table-size CNC router.

How does a 4x6 CNC router table work?

4x6 CNC router tables are the most common ones. A CNC router with a bed size of 4 by 6 feet can easily accommodate in a smaller space. Usually, small manufacturing projects or home use for a hobbyist needs not more than that. So, how can this machine be so efficient?

Design and processing are the two primary steps to complete at the beginning. A digital blueprint design with the dimensions, shapes, and features of the final product is first created with CAD software. Then the digital design uses CAM software to create G-code instructions according to the model. Once done, the machining process starts sequentially,

✔ The material is secured and clamped on the 4X6 bed. Select cutting tools according to the cutting configuration and material type.

✔ Calibrate the machine and take a dry run. This test run ensures zero errors with the G-code and also ensures precision. Any misconfiguration can be found in the dry run to solve.

✔ The machine starts with the command and starts cutting moving the spindle and bed along X, Y, and Z axes.

✔ Just like any other CNC machine, the production of a hobby CNC router also requires finishing and inspection.

The 4X6 bed size will only allow the hobbyist to complete their manufacturing within the space they can afford. And these machines are highly capable of doing constant manufacturing processes like heavy CNC routers.

4x6 Hobby CNC Router Machine Features

⇲ The 4x6 CNC machine body structure adopts high-quality steel pipe welding and strong bearing strength.

⇲ The 4x6 CNC machine adopts Taiwan linear square guide rail, operating smoothly and, with high accuracy.

⇲ X, Y, and Z axis adopt ball screw transmission with high precision.

⇲ The 4x6 CNC router machine adopts a high-speed stepper motor and drives.

⇲ 2.2KW water cooling spindle, strong and free maintenance, continuous working.

⇲ Aircraft aluminum T-slot working table covered PVC protects the tools from breaking, and T-slot with clamps makes it convenient to fix the materials.

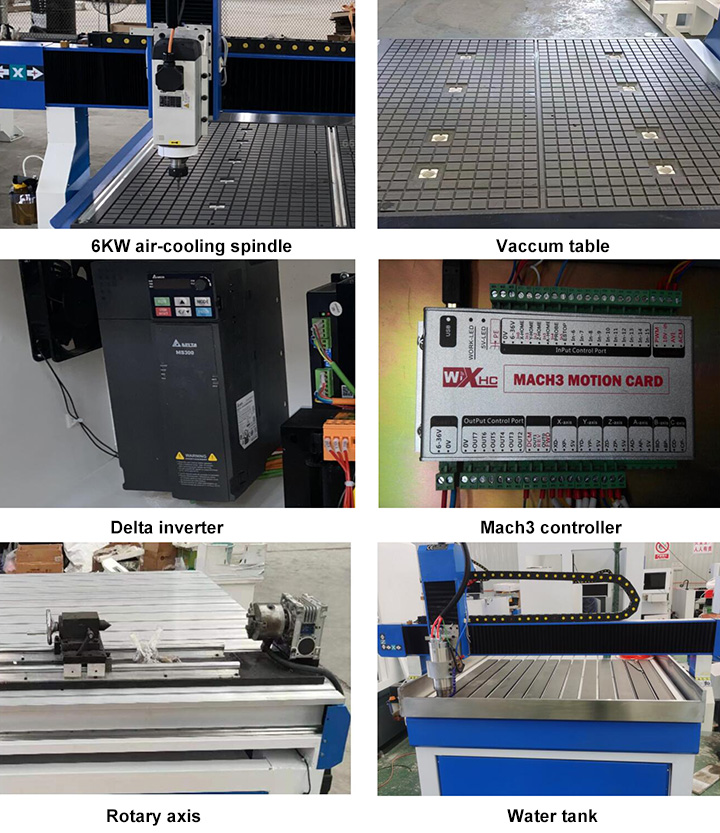

⇲ The vacuum table is optional and can absorb the materials automatically by vacuum pump, there is no need to fix the materials.

⇲ Good software compatibility, can be compatible with ArtCAM, Type 3, JDPaint and UcanCAM.

4x6 Hobby CNC Router Machine Technical Parameters

| Model | STG1218 |

| Table Size | 4x6 |

| XYZ Working Size | 1200*1800*200 mm |

| Machine body | Cast iron |

| Table Surface | T-slot table (Vacuum table for option) |

| XY structure | Ball screw drive, HIWIN square linear rail |

| Z structure | Ball screw drive, HIWIN square linear rail |

| Spindle | 2.2kw water cooling spindle |

| Spindle speed | 0-24000 RPM |

| Drive motor | Stepper system |

| Max Rapid Travel Rate | 30000 mm/min |

| Max Working Speed | 8000 mm/min |

| Control System | DSP controller |

| Software | Type3, Artcam, Ucancam |

| Command | G code |

| Working Voltage | AC220/50HZ/60HZ |

| Machine Size | 2450mmX1900mmX1800mm |

| Net Weight | 650KG |

| Dust Collector | optional |

| Remark | We can customize the model for any machining size |

4x6 Hobby CNC Router Machine Options

⇲ Vacuum table with 5.5kw vacuum pump.

⇲ Mach3 CNC controller.

⇲ Dust collector system.

⇲ AC servo motors.

⇲ Air-cooled spindle.

⇲ Rotary device 4th axis.

⇲ Water tank.

4x6 Hobby CNC Router Machine Applications

Woodworking

Wooden doors and furniture, windows, tables and chairs, cabinets and panels, 3D wave plates, MDF, computer desk, musical instruments, etc.

Advertising

Billboard, logo, sign, 3D characters cutting, acrylic cutting, LED/neon channel, literal-hole cut, lightbox mold, stamp, mold, etc.

Die Industries

Copper sculpture, aluminum engrave, metal molds, plastic sheeting, PVC, etc.

Decorations

Acrylic, density board, artificial stone, organic glass, soft metals like aluminum and copper, etc.

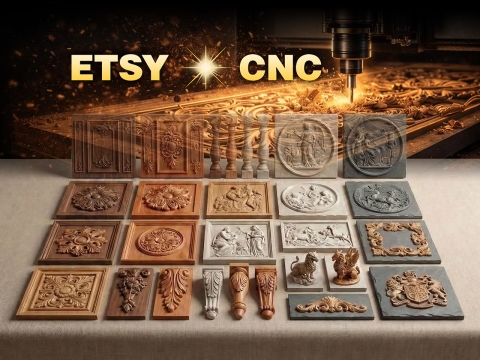

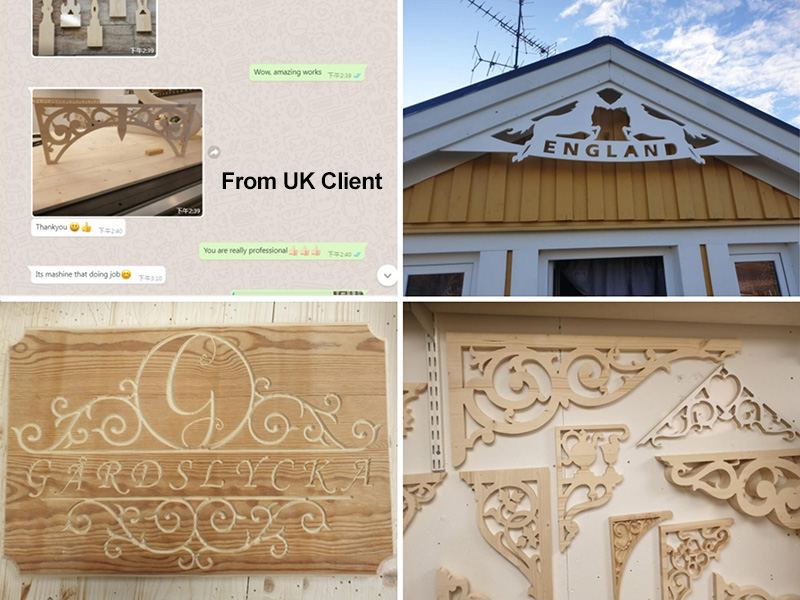

4x6 Hobby CNC Router Machine Projects

4x6 Hobby CNC Machine Package

Benefits of Cheap CNC Router

CNC routers are not the cheapest machinery in the industry. It brings comfort that these days cheaper and smaller CNC machines are available. Affordable CNC routers like hobby CNC routers are very popular with their capability considering the price. Cheaper hobby CNC routers barely compromise in technology but the production rate. Since these routers come at an affordable rate what could they be missing?

Here, take a look at the usefulness and drawbacks of a cheap CNC router.

| Pros | Cons |

|---|---|

| Affordable entry point for beginners and hobbyists. | Cheaper materials and components may wear out faster. |

| Easier to learn and operate for those new to CNC machining. | May not offer the same level of precision as higher-end models. |

| Can handle a variety of materials and project types. | Less powerful spindles may limit the types of materials that can be cut. |

| Space-efficient, suitable for home workshops and small spaces. | Fewer advanced features compared to more expensive models. |

| Access to online forums and resources for help and advice. | Many models require assembly and calibration, which can be time-consuming. |

| Lightweight and easy to move or store when not in use. | Cheaper models may be noisier during operation. |

Tips for optimal use!

Remember, only hobby CNC routers are not cheaper ones. A compact hobby CNC machine can also cost nearly as much as an industry CNC router. To make sure that your routers only earn a good fortune, follow these tips suggested by our CNC router specialists.

✔ Ensure the bed is level and secured and tram the spindle.

✔ Use appropriate cutting tools considering the material.

✔ Lubricate moving parts and keep the machine clean.

✔ Use updated CAD/CAM software and optimize G-code by running simulations.

✔ Choose and secure the material on the cutting bed properly.

✔ Avoid overloading and set the correct speeds.

✔ Install safety features and use protective gear.

✔ Implement dust control and clean your machine regularly.

Brent Lasley

Anonymous

Pavlínka

Celkově vzato je to skvělý CNC router. Použil jsem to všechno. Tato sada je skvělá pro svou nízkou cenu. Nepotřebuje dlouhou montáž. Jen je potřeba propojit elektriku. Příští rok přidám ke svým výrobkům skříně a koupím větší CNC na výrobu karbinet.