5W UV Laser Engraving Machine for Metal, Glass, Plastic

This video shows how does 5W UV laser engraving machine etch stainless steel, glass, leather, wood, stone, acrylic, and plastics with fine details.

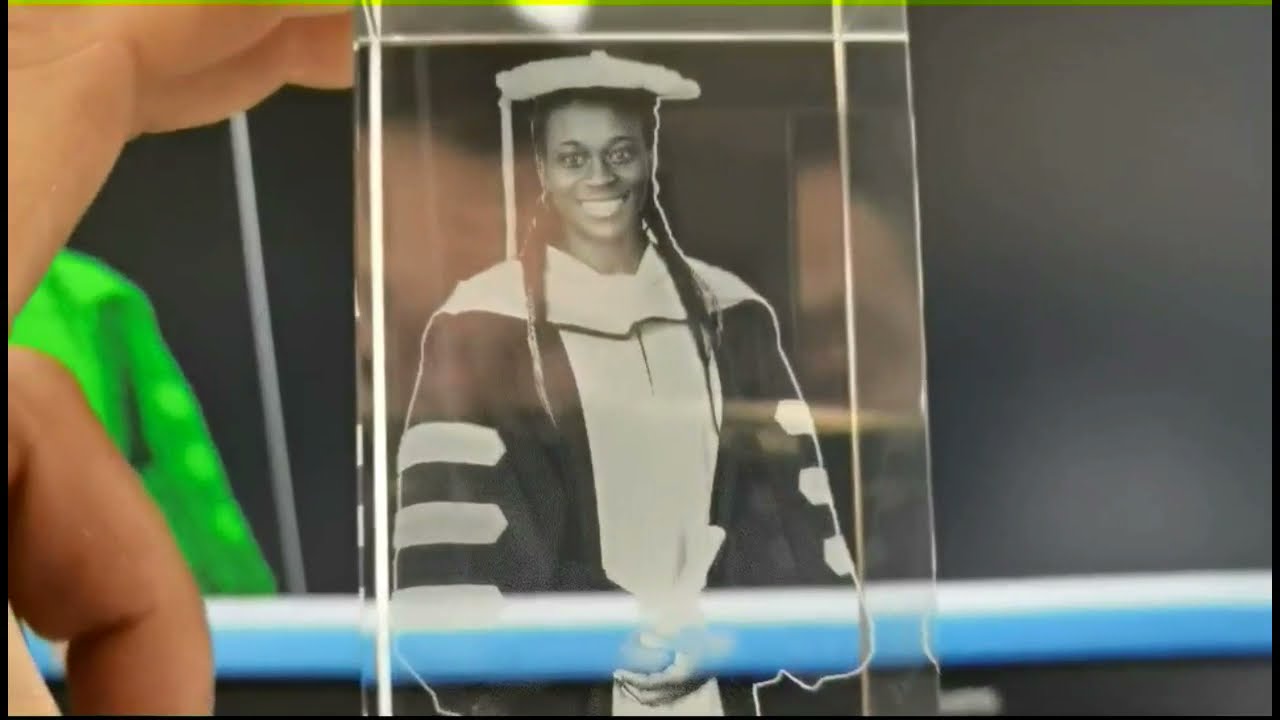

3D inner laser engraving machine is used for engraving photo, pattern, or text in crystal to make custom personalized 3D crystal gifts & crafts, as well as for glass cube, sculpture, block, or bubblegram.

When it comes to gifts and crafts made by laser, the first thing I think of is the inner crystal engraving. The outside of the crystal is smooth and hard, without any gaps. People who don't know the process principle behind it really can't figure out how this internal pattern is made?

In fact, most of the crafts and gifts you usually see are not real crystals, but artificial crystals. "Laser" is the most useful tool for "internal engraving" of man-made K9 crystal (also called "crystal glass"). Using laser engraving technology, the plane or 3D pattern is "laser engraved" in the crystal glass.

These glass and crystal handicrafts are made with a computer-controlled laser engraving machine. The laser machine injects a certain wavelength of laser light into the glass or crystal, causing a specific part of the inside to burst into bubbles to form a preset shape.

The principle of laser engraving is actually very simple. For a laser to be able to engrave glass, its energy density must be greater than a certain critical value, or threshold value, to destroy the glass, and the energy density of the laser somewhere is related to the size of its spot at that point. The same laser, the smaller the spot The greater the energy density generated in the place. In this way, through proper focusing, the energy density of the laser can be lower than the glass damage threshold before it enters the glass and reaches the processing area, and exceeds this critical value in the area to be processed, and the laser generates pulses in a very short time. Its energy can cause the crystal to be heated and ruptured in an instant, resulting in extremely small white spots, engraving a predetermined shape inside the glass.

1. Laser internal engraving is an environmentally friendly and energy-saving process for deep processing in the glass and crystal industries.

2. The graphics are inside the glass or crystal.

3. It looks particularly beautiful after refraction.

4. Compared with traditional engraving, its preservation period is longer.

5. Compared with 3D printing, it can engrave any plane and 3D geometry.

6. There is a tailing phenomenon in the engraving point, and the one-way limit of the view is very large.

7.Compared with flat printing, the internal engraving is done with white dots instead of writing black letters.

8. Matching lights in a dark environment can highlight its value.

9. If you use it to build a three-dimensional model, you can achieve a special transparency effect.

10. Short processing time and high production efficiency.

The engraving of glass is usually difficult to control. Follow the steps below to make a smooth frosted surface: paint a little on the area to be engraved and wash it off, cut out a piece of newspaper or napkin that is slightly larger than the area to be engraved, and use water. Soak the paper completely and squeeze out the excess water. Put the wet paper on the area to be carved and flatten it without creases. Put the glass in the engraving machine, engrave the paper when the paper is still wet, then take out the glass, remove the remaining paper, and then clean the surface of the glass. Under normal circumstances, the laser power setting should be smaller, the precision should be set at 300dpi, and the engraving speed should be faster. You can try to use large-size lenses for engraving.

Note: You should be more careful when engraving leaded crystals with lasers. Leaded crystals and ordinary crystals have different expansion coefficients, which can cause crystal cracks or breakage during engraving. A smaller power setting can avoid this problem, but you should always guard against it in case of rupture.

This video shows how does 5W UV laser engraving machine etch stainless steel, glass, leather, wood, stone, acrylic, and plastics with fine details.

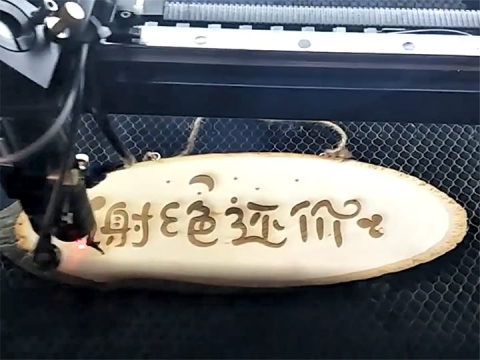

You will understand how does laser wood engraving machine for DIY custom wood crafts in this video, which can also make signs, logos, painting, arts, gifts.

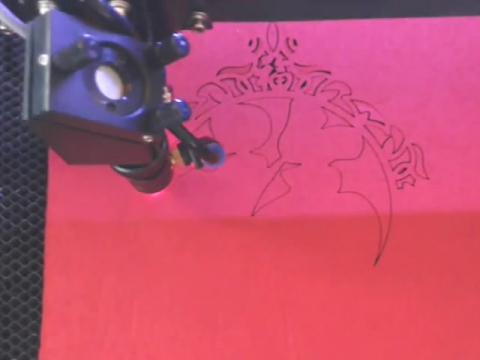

As a CO2 laser engraver cutting machine cuts the felt, it forms a very clean cut with burning the edge of the fabric, and makes awesome precise results.