This was my first time cutting marble with a CNC machine and was impressed by how great the waterjet cut. Every cut was clean and smooth, without dust like saw blade cutting. Exactly what I needed.

Industrial CNC Waterjet Cutting Machine for Every Need

Looking for a powerful and high-precision water jet cutter for cutting through thick metal, stone, glass, tile, plastic, composites, and heat-sensitive materials? Check out this industrial CNC waterjet cutting machine for a wide range of materials. STYLECNC's automated water jets deliver precision cuts at thicker thicknesses without sacrificing edge quality and thermal distortion, and minimize material waste for cost-effective operations.

- Brand - STYLECNC

- Model - STWJ3020-3X

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 1980mm x 3000mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

A waterjet cutter is a powerful cutting tool that uses an ultra-high-pressure water jet mixed with abrasives to cut through metal, stone, glass, and more materials. A water jet cutting machine uses a high-pressure pump to intensify water to extremely high pressure, which is then ejected through a tiny nozzle to form a high-speed water jet at 1,000 meters per second (up to 2-3 times the speed of sound) to cut a variety of materials.

Industrial CNC Waterjet Cutting Machine Advantages & Benefits

• No thermal deformation - No heat is released during the cold waterjet cutting process, which can prevent material deformation or changes in mechanical properties caused by high temperatures.

• High-precision cutting of complex shapes - Waterjets can precisely cut complex curves and tiny details (with an accuracy of up to ±0.1 mm), making them perfect for precision molds and artwork.

• Diverse cutting materials - Waterjets are powerful enough to cut through virtually any material. The cold cutting technology offers irreplaceable advantages and benefits in cutting brittle materials (metals, plastics, ceramics, glass, composites, and more), especially multi-layer or heterogeneous materials. In addition, Waterjets can cut through soft materials with ease while achieving diamond-like sharpness on hard materials.

• Minimal material waste - Narrow kerfs (approximately 0.5-1.5 mm) conserve raw material and are ideal for processing precious materials.

• Safe and environmentally friendly - Low noise, no toxic gases or dust, and filtered and recycled wastewater.

Industrial CNC Waterjet Cutter Features

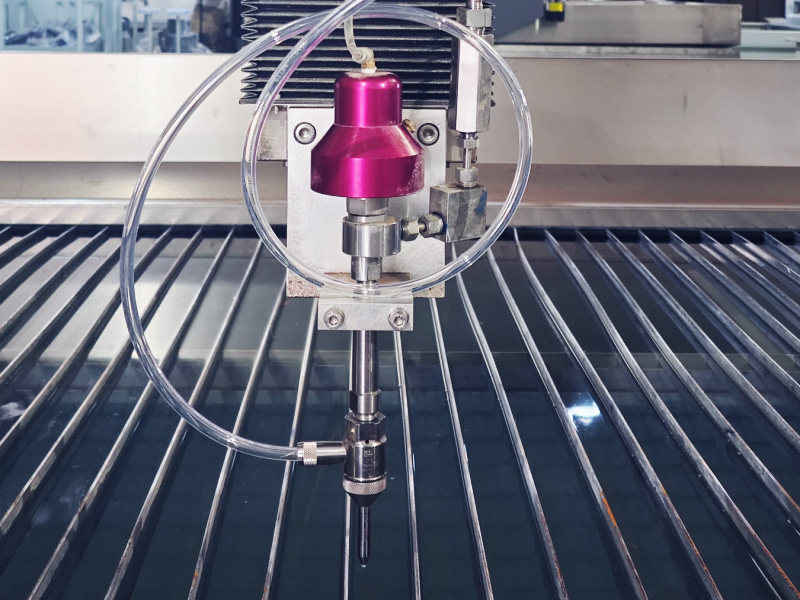

Gantry Cutting Table

• The waterjet cutting table consists of X, Y, and Z-axis drives, a water tank, a cutting head, lubrication components, and a servo drive system, making it professional for creating a variety of complex, large parts.

50-HP Booster Pump

• Designed in accordance with CE and ISO9001 standards.

• The booster pump utilizes top-quality brand components.

• Servo proportional pressure control.

• Different pressure settings for different materials.

• Stable operating pressure and easy maintenance.

3-Axis Waterjet Cutting Head

• Versatile, easy to use, low maintenance, suitable for 2D cutting of various materials.

Automatic Abrasive Supply System

• Automatically delivers abrasive to the cutting head and automatically alarms when abrasive is low. The simple structure ensures easy operation and maintenance.

Weihong CNC Controller System Software

• This controller system is user friendly, and is easy to operate for beginners, and supports direct import of CAD files, cutting a variety of complex designs with ease.

• The built-in cutting parameters allow users to customize them. The operators simply select the material type, thickness, and finish quality to achieve optimal cuts.

Industrial CNC Waterjet Cutting Machine Specifications

High Pressure Pump Parameters

| High Pressure Pump Model | 50HE |

| Power | 37kw/50hp |

| Max. pressure | 400Mpa /4000bar |

| Working pressure | 300-350Mpa |

| Max. oil discharge | 104L/min |

| Max. Flow rate | 3.7L/min |

| Max.diameter of orifice | 0.33mm |

| Power supply | 380V 50hz |

| Inlet water pump max. flow rate | ≥15.1L/min |

| Water pressure | ≥0.1Mpa |

| Cooling system | Build-in air cooling system |

| Dimension(L*W*H) | 1800mmx1000mmx1400mm |

| Weight | 1130Kgs |

| Cutting materials | Glass, marble, granite, aluminum, copper, steel, and more |

Waterjet Cutting Table Parameters

| Model | STWJ3020-3X |

| Brand | STYLECNC |

| Max.travel range of X-Y | X=3000mm Y=1980mm |

| Travel range of Z axis | 150mm |

| Servo system | WEIHONG |

| Cutting accuracy | ±0.1mm( 3 axis cut) |

| Re-positioning accuracy | ±0.025mm/m |

| Max. moving speed | 18000mm/min |

| Max. Loading weight | 800KG/m2 |

| Overall dimension(footprint) | 4800mmX2600mm |

| Power supply | AC 380V 50/60Hz |

| Professional Water jet software | NC Studio V10 |

| PC | Windows 10 64-bit |

| Display screen | ≥19" |

Automatic Abrasive Feeding System Parameters

| Dimension(L*W*H) | 600mm*600mm*1400mm |

| Weight | 100Kg |

| Max.capacity | 150Kg |

| Max. air pressure supply | 0.2Mpa |

| Voltage | 24V |

| Power rate | 36W |

AC Five-Axis Water Jet Cutting Head (Optional)

• AC 5-axis waterjet cutting system, with the A-axis capable of ±120° rotation for 0°-75° bevel cutting.

• Vertical cut taper compensation.

• The five-axis cutting head comes with a laser sensor to collect position information, allowing the controller to determine the correct Z-axis height at different points, thereby improving cutting accuracy for large slabs. The 5-axis waterjet cutting system is ideal for bevel cutting large-sized tiles or marble.

• The hollow rotary reducer offers a simple and compact structure, reduced weight, and enhanced dynamic performance.

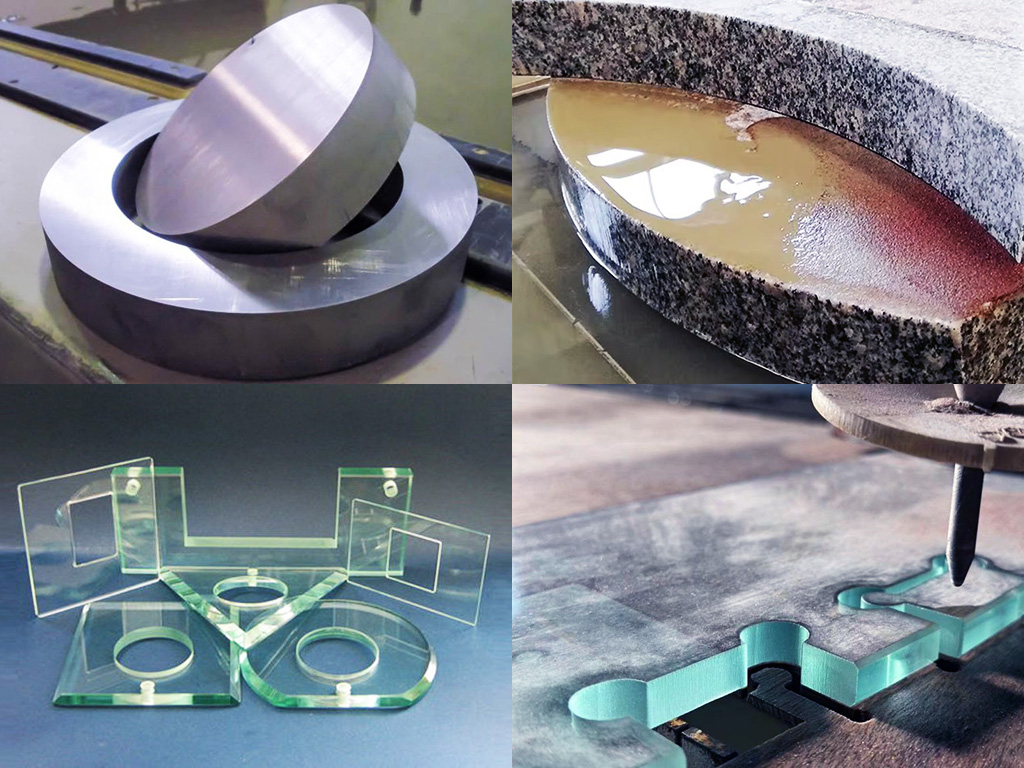

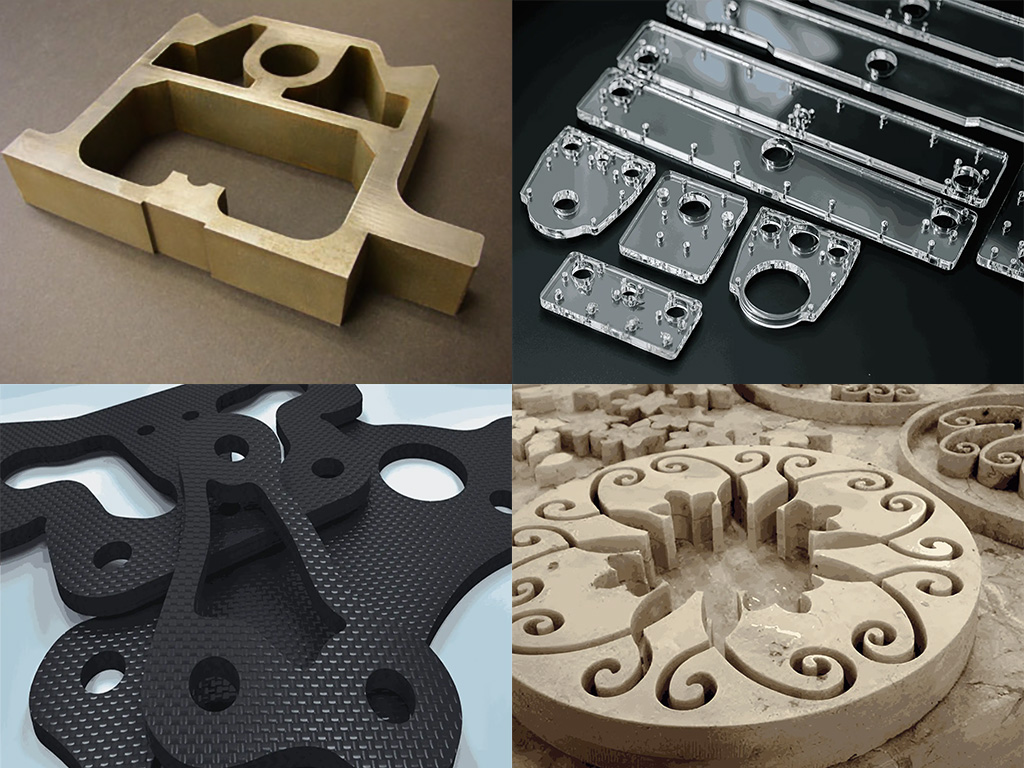

Industrial CNC Water Jet Cutter Applications

Water jet cutting technology is popular in a variety of applications and uses due to its cool cutting properties (no heat-affected zone).

• Metalworking - Waterjets can cut a variety of metals, suhc as steel, titanium alloys, and aluminum alloys, making them ideal for precision aerospace components.

• Composites - Waterjets can cut carbon fiber and fiberglass, avoiding delamination or burrs.

• Stoneworking - Waterjets can cut marble, granite, and ceramic tile for decorative and artistic applications.

• Automotive Manufacturing - Waterjets can cut not only automotive interior materials but also body panels and bulletproof glass.

• Electronics and Medical Devices - Waterjets are experts at precisely cutting circuit boards and silicon wafers, as well as medical devices used in surgery.

Industrial CNC Water Jet Cutting Projects