There is a lot to consider before you buy a CNC machine. You have to decide what type of CNC machine you want, which features it needs to have, and how you're going to pay for it. The listed ways below are the payment methods we accept.

Telegraphic Transfer

TT (Telegraphic Transfer) is the method of payment by electronic transfer of funds from one bank account to another.

Telegraphic transfers are also known as telex transfers, abbreviated TT. They can also refer to other types of transfers. The payment abbreviation, as is often the case, is utilized to speed discussions in professional circumstances. Telegraphic transfer is a fast nature of the transaction. Generally, the telegraphic transfer is complete within two to four business days, depending on the origin and destination of the transfer, as well as any currency exchange requirements.

e-Checking

Credit Card

Credit card payments with Visa or Mastercard are supported.

If you're shopping for a new or used CNC machine in today's marketplace. This list explores the easy-to-flow steps a buyer would take to purchase a CNC machine. Let's begin.

Step 1. Consult: we will recommend the most suitable CNC machines to you after being informed by your requirements.

Step 2. Quotation: We will supply you with our detail quotation according to our consulted machines with the best quality and price.

Step 3. Process Evaluation: Both sides carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

Step 4. Placing Order: If you have no doubts, we will send you the PI (Proforma Invoice), and then we will sign a sales contract.

Step 5. Production: We will arrange the production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the buyer during the production.

Step 6. Inspection: The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before out of factory.

Step 7. Delivery: We will arrange the delivery as the terms in the contract after the confirmation by the buyer.

Step 8. Custom Clearance: We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 9. Support and Service: We will offer professional technical support and service by Phone, Email, Skype, WhatsApp around the clock.

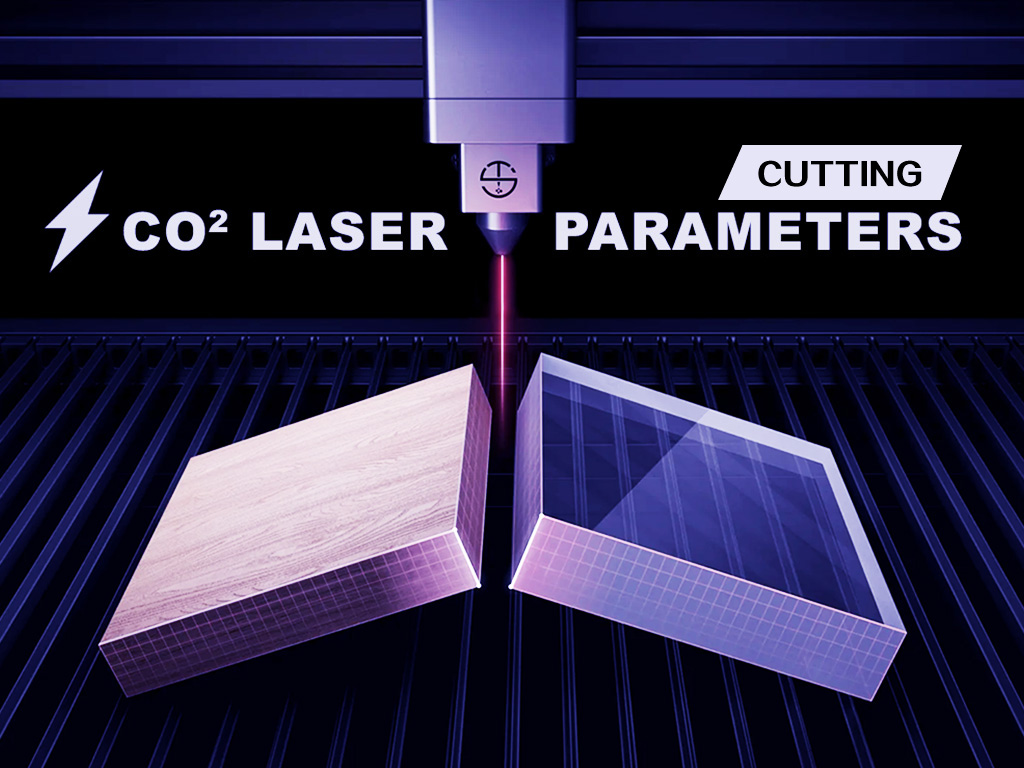

A CO2 laser cutter is a thermal cutting tool that can cut a variety of non-metallic materials, including wood, acrylic, paper, leather, fabric, rubber, and foam. CO2 lasers are ideal for cutting materials with high absorption rates at the laser wavelength, offering fast cutting speeds and high precision.

CO2 lasers can cut through materials of varying thicknesses at various speeds, depending on laser power, as well as material type and hardness. Higher power lasers are capable of cutting thicker materials at faster speeds. In most cases, CO2 laser cutters work with a power range of 40 watts to 300 watts to cut through wood with a thickness of 1 mm to 20 mm at a speed of 1000 mm/min to 9000 mm/min, acrylic with a maximum thickness of 40 mm at a speed of around 1200 mm/min, leather and cloth with a thickness of 0.75 mm to 10 mm at a speed of 500 mm/min to 12000 mm/min, and paper with a thickness of 0.5 mm to 11 mm at a speed of about 3000 mm/min.

Best CO2 Laser Cuttable Materials

Wood

• Solid wood (such as birch, poplar, red oak, cherry)

• MDF (medium-density fiberboard)

• Plywood

• Cork

Plastics

• Acrylic

• PP (polypropylene)

• PVC (polyvinyl chloride)

• ABS (acrylonitrile butadiene styrene)

Paper

• Paper Sheet

• Cardstock

• Cardboard

Leather & Fabric

• Organic fabrics (such as polyester)

• Line fabric (multi-layer)

• Artificial fabric (chemical fiber fabric)

• Leather (genuine leather and artificial leather)

Foam (Polystyrene)

• HIPS

• EPS

• XPS

CO2 Laser Cutting Thickness & Speed & Kerf Chart

| Material | Thickness (mm) | Speed (mm/min) | Assist Gas | Kerf (mm) |

|---|---|---|---|---|

| Organic Glass | 10 | 800 | N2 | 0.7 |

| Polyester Felt | 10 | 2600 | N2 | 0.5 |

| Line Fabric (Multi-layer) | 15 | 900 | N2 | 0.5 |

| Cardboard | 0.5 | 3000 | N2 | 0.4 |

| 2.6 | 3000 | N2 | 0.5 | |

| Quartz Glass | 1.9 | 600 | 0.2 | |

| PP (Polypropylene) Sheet | 5.5 | 700 | N2 | 0.5 |

| Polystyrene Sheet (HIPS, EPS & XPS Foam) | 3.2 | 4200 | N2 | 0.4 |

| PVC Sheet | 4 | 1700 | Air | N/A |

| Organic Glass | 10 | 1200 | ||

| Bakelite Board | 5 | 2100 | ||

| Fiberboard | 15.6 | 4500 | N2 | |

| Multi-layer Plywood | 6.2 | 9000 | ||

| PVC (Polyvinyl Chloride) Laminate | 3.1 | 10500 | ||

| Chipboard | 3.9 | 18000 | ||

| 3.1 | 22500 | |||

| Acrylamide Board | 2.8 | 33900 | ||

| 3.2 | 29700 | |||

| 3.2 | 29700 | |||

| Acrylic | 2.0 | 1000 | N/A | |

| Artificial Leather | 0.8 | 2500 | ||

| Gypsum Board | 9.0 | 500 | ||

| Plywood | 10.0 | 1100 | ||

| Heat-Resistant Glass | 2.2 | 500 | ||

| Rubber Sheet | 5 | 500 | ||

| Leather | 4 | 2200 | ||

| Artificial Fabric | 6.5 | 2200 |

CO2 Laser Power and Cutting Thickness Chart

| Material | Laser Power | ||||

|---|---|---|---|---|---|

| 40W | 50W | 60W | 80W | 100W | |

| Cutting Thickness | |||||

| Acrylic | 3mm | 5mm | 5-8mm | 6-10mm | 10-12mm |

| MDF | 1mm | 2mm | 4mm | 5mm | 6mm |

| Plywood | 3mm | 5mm | 8mm | 10mm | 13mm |

| PVC | 2mm | 3mm | 4mm | 5mm | 8mm |

| Rubber | 2mm | 2mm | 3mm | 4mm | 5mm |

| Leather | 2mm | 3mm | 4mm | 5mm | 7mm |

| Fabric | 2mm | 3mm | 4mm | 6mm | 7mm |

| Paper | 3mm | 4mm | 5mm | 7mm | 8mm |

| Material | Laser Power | ||||

|---|---|---|---|---|---|

| 130W | 150W | 180W | 220W | 300W | |

| Cutting Thickness | |||||

| Acrylic | 12-25mm | 17-28mm | 20-30mm | 20-35mm | 20-40mm |

| MDF | 8mm | 10mm | 10mm | 12mm | 18mm |

| Plywood | 15mm | 15mm | N/A | N/A | N/A |

| PVC | 9mm | 10mm | N/A | N/A | N/A |

| Rubber | 6mm | 7mm | N/A | N/A | N/A |

| Leather | 8mm | 10mm | N/A | N/A | N/A |

| Fabric | 8mm | 10mm | N/A | N/A | N/A |

| Paper | 10mm | 10mm | N/A | N/A | N/A |

All charts are for reference only. The actual cutting thickness will vary depending on material properties and cutting parameters such as power and speed.

Industry applications such as metalworking, engraving, woodworking, and others now depend heavily on CNC (Computer Numerical Control) equipment. Their accuracy, productivity, and aptitude for managing intricate assignments are well-known attributes. A lot of attention has been paid to Chinese-made CNC machines throughout the years. Their affordability is one of the key causes of this. Still, a lot of prospective customers wonder: Are Chinese CNC machines any good?

This article will examine the features, dependability, performance, and quality of CNC machines made in China to provide an answer to that query. We'll also discuss how long they last, if they're appropriate for small enterprises, and offer advice on selecting a quality machine.

Quality of Chinese CNC Machines

Prices are sometimes the first thing that comes to mind when we think about Chinese items. There are questions regarding quality because Chinese CNC machines are far less expensive than equivalent models in Europe or America. Chinese manufacturers were once known for taking shortcuts. However, in recent years, many Chinese enterprises have improved their production standards, especially in fields like CNC technology.

• Better Technology: Many Chinese manufacturers now use advanced technology to produce CNC machines that meet international quality standards. This means machines are more precise, durable, and reliable.

• Improved Quality Control: Factories have adopted stricter quality control processes to ensure that their machines can compete globally. Today, you’ll find many Chinese CNC machines that comply with certifications like ISO9001, which guarantees certain levels of quality and performance.

• Global Collaboration: Some Chinese manufacturers partner with international companies to produce high-quality machines. This collaboration allows them to incorporate better designs and use higher-quality materials.

In general, the quality of Chinese CNC machines has improved significantly. Chinese CNC machines are used in many industries, such as metal fabrication, woodworking, and automotive since they produce high-quality outputs at an affordable price.

Are Chinese CNC Machines Any Good?

Let's now discuss the primary question "Are Chinese CNC machines any good?" The answer isn’t as easy as a "yes" or "no" because it relies on various things, such as the individual equipment, the manufacturer, and what you plan to use it for. Investing in Chinese CNC machines can be wise, particularly if you're searching for a cost-effective option. To guarantee that you receive a machine that satisfies your needs, you must select a reliable manufacturer. These are some important things to remember.

1. Affordability: Compared to machines from Europe or the United States, CNC machines made in China are far less expensive. Because of this, they are a desirable choice for small and medium-sized companies without the funding for luxury brands. Cheaper doesn't always result in worse quality. Excellent value for the money is offered by many CNC machines made in China.

2. Varied Quality: The quality of Chinese CNC machines can vary from one manufacturer to another. While some businesses may offer more affordable, less durable equipment, others may build high-quality machines that function well and survive for years. Doing your homework on a brand is crucial before making a purchase.

3. Customer Satisfaction: Many users report positive experiences with Chinese CNC machines, particularly in industries like woodworking and metalworking. They find the machines capable of handling their production needs efficiently.

4. Customization Options: Customizable features are available on several Chinese CNC manufacturers' machines. This lets customers select particular parts, apps, or features according to their needs. This flexibility can offer excellent value because it allows you to customize a machine to meet your particular needs without having to pay extra for things that aren't necessary.

5. Availability of Spare Parts: One advantage of buying Chinese CNC machines is the availability of spare parts. Many Chinese manufacturers provide easy access to replacement parts, which can be shipped quickly and at lower costs compared to parts for Western machines. This can reduce downtime and keep production running smoothly.

Performance and Reliability of Chinese CNC Machines

The performance and reliability of CNC machines are critical for any business, as they directly impact production efficiency. So how do Chinese CNC machines fare in terms of performance and reliability?

Performance

Chinese CNC machines are well-known for their high performance in general-purpose activities such as cutting, milling, and engraving. These machines can deal with a variety of materials, including wood, plastic, and metal. Many Chinese CNC machines can operate at fast speeds, allowing enterprises to produce more in less time.

Advanced models are appropriate for businesses that need exquisite detailing, like jewelry production and sign engraving, because they can handle complex designs and high-precision activities. In terms of performance, many Chinese CNC machines are comparable to models made in Europe and America, particularly when used in non-industrial environments.

Reliability

A crucial component of every CNC machine is reliability. When properly maintained, Chinese CNC machines can be quite dependable. Regular upkeep such as oiling, cleaning, and component inspections can help the equipment last longer. However, when purchasing from less popular manufacturers, some customers have occasionally reported having problems with warranty claims or customer assistance.

Chinese CNC machines are highly dependable when maintained regularly and work well in a variety of applications. Selecting a model that aligns with your manufacturing requirements is crucial.

Common Features of Chinese CNC Machines

Chinese CNC machines often come with a set of features that make them versatile and user-friendly. Here are some of the common features you’ll find,

• Affordable Pricing: The biggest selling point of CNC machines made in China is their affordability. These machines cost significantly less than models from other countries, making them accessible to businesses of all sizes.

• Wide Range of Models: Chinese CNC machines range from entry-level desktop units for beginners to industrial-grade machines for mass production, available in a variety of sizes and models. This range enables you to select a machine that meets your unique requirements.

• User-Friendly Interfaces: Easy-to-use control panels and intuitive software are standard on a lot of CNC machines made in China. This makes them usable even by novices who might not have much background in CNC technology.

• Multi-Functionality: Most Chinese CNC machines can handle multiple tasks, such as engraving, cutting, milling, and drilling. This versatility makes them suitable for various industries, including woodworking, metalworking, and plastic fabrication.

• Customization Options: You can adjust the machine to suit your production demands thanks to customization possibilities offered by certain Chinese manufacturers. Customization can improve the machine's functionality, whether it's through spindle upgrades or feature additions.

How to Choose a Good Chinese CNC Machine?

It might be difficult to select the best CNC machine, especially with so many alternatives available. The following guidelines will assist you in choosing a high-quality Chinese CNC machine. You can select a CNC machine that meets your company's requirements by using the procedures outlined here to help you make an informed choice.

1. Research the Manufacturer: Not every Chinese company manufactures similarly high-quality machinery. Seek out producers who have a solid track record, glowing testimonials, and dependable customer service. It can also be beneficial to look for international certifications such as ISO9001.

2. Know Your Requirements: Determine your needs for the machine before making a purchase. Will you be working with wood, metal, or plastic? Do you require extreme precision? Selecting the ideal machine for your organization can be made easier if you are aware of your needs.

3. Check for Warranties and Support: A good warranty can give you peace of mind in case something goes wrong. Also, make sure the manufacturer or supplier provides customer support, so you can get assistance if needed.

4. Read Reviews: User reviews can provide valuable insights into the performance and reliability of a machine. Look for reviews from businesses similar to yours to get a better idea of how well the machine will perform in your setting.

5. Evaluate Technical Specifications: Pay close attention to the technical specifications of the CNC machine. Look for details like the machine's speed, cutting accuracy, and the range of materials it can handle. Make sure the specifications align with your production needs.

Are Chinese CNC Machines Suitable for Small Businesses?

Cost is frequently a key consideration for small businesses when buying equipment. Chinese CNC machines are a popular option for small and medium-sized businesses (SMEs) because they are usually less expensive than their Western equivalents. Are they appropriate for such companies?

Chinese CNC machines are a wonderful solution for small companies for various reasons. First, they are affordable, so businesses on a tight budget can use them. Local businesses can compete in their markets by making cost-effective investments in CNC technology.

Scalable CNC machines are common in China. This suggests that companies can begin with a simple model and then update as they expand. Small businesses that intend to grow over time and require equipment that can adjust to their rising production needs will find this flexibility ideal.

The ease of use is another benefit. Chinese CNC machines are usually easy to operate thanks to their user-friendly interfaces. Small firms will benefit from this as it saves time and lessens the need for in-depth training. All things taken into account Chinese CNC machines offer a good mix of affordability and functionality, which makes them an excellent choice for small enterprises trying to streamline their processes.

Pros and Cons of Buying a Chinese CNC Machine

Like any product, Chinese CNC machines have advantages and disadvantages of their own. If you perform an in-depth study and consider your particular needs, you may make a better decision. Examine carefully the advantages and disadvantages of buying one.

Advantages of a Chinese CNC Machine

1. Affordable: Chinese CNC machines are much cheaper than those made in Western countries. This affordability makes them an attractive option for small businesses and hobbyists who may not have a large budget.

2. Versatile: A great deal of work may be done by many CNC machines made in China. They are capable of milling, engraving, and cutting a variety of materials, such as plastic, metal, and wood. This adaptability makes them suited for numerous applications.

3. Customizable: Some manufacturers allow for customization of their CNC machines. This means you can modify features or add components based on your specific needs. Customization can help you get the exact machine that fits your business requirements.

4. Wide Range of Models: China offers a wide range of CNC machines for sale. From compact desktop machines for amateurs to bigger industrial machines for heavy-duty manufacturing, there are types to suit every demand.

5. Rapid Production: Chinese manufacturers often have faster production times. This means you can get your machine sooner than from some other countries, allowing you to start your projects more quickly.

6. Availability of Spare Parts: Spare components are widely available from numerous Chinese manufacturers. This accessibility guarantees that you can quickly replace parts when necessary, cutting down on downtime and maintaining the efficiency of your operations.

Drawbacks of a Chinese CNC Machine

1. Varied Quality: The quality of Chinese CNC machines can differ significantly from one manufacturer to another. While some machines are high-quality, others may not meet your expectations. It is crucial to research and choose a reputable brand.

2. Customer Support: Some Chinese manufacturers may provide limited customer support, especially for international buyers. This can make it challenging to get help when issues arise, leading to potential delays in your production.

3. Warranty Issues: Warranty claims can sometimes be difficult to navigate. Depending on the manufacturer, you might face challenges when trying to claim a warranty or receive service, which could lead to frustration if problems occur.

How Long Do Chinese CNC Machines Last?

The longevity of a CNC machine depends on several factors, such as its quality, usage pattern, and level of maintenance. How long do Chinese CNC machines last?

Good Chinese CNC machines last a long time, especially when they come from reputable manufacturers. Some consumers report using their products for over ten years with proper maintenance. Regular maintenance can extend the life of any CNC machine. This entails cleaning, lubricating, and replacing worn-out parts. Most Chinese CNC machines come with maintenance guidelines that, if followed, can significantly increase the machine's lifespan.

A machine will wear down faster with increased use. However, a well-built Chinese CNC machine can endure for several years, even with severe use. A high-quality Chinese CNC machine may provide excellent value for money and a long lifespan with regular maintenance.

Final Thought

Many firms can benefit from using Chinese CNC equipment. They come in a variety of models, are reasonably priced, and are useful. Many additionally provide opportunities for customization to fulfill certain requirements. Selecting a reliable manufacturer is crucial because quality can differ.

Investigate your options because problems with customer service and warranties could come up. All things considered, a Chinese CNC machine can help you increase efficiency and expand your company with the appropriate strategy. You can choose a machine that is ideal for your needs by assessing the benefits and drawbacks.

We typically build CNC machines to standard designs, however in some cases we can provide custom services as listed below.

1. Table sizes can be larger or smaller depending on your specific CNC machining needs.

2. Your logo can be put on the machine whether you are an end user or a dealer.

3. The appearance and color of the machine are optional according to your personal preference.

4. Individual machine specifications can be designed in a customer-oriented manner.

We have free online training. You can come to STYLECNC for training in factory. We can also assign technician for door-to-door training with some charge.

1. User Manual.

We provide document instructions for CNC machine installation, operation and debugging steps with pictures and texts.

2. Staff training.

Prepare training plans and make training handouts. After you purchase STYLECNC CNC machine, we can provide systematic training for users.

3. Telephone support.

After we receive a user's technical support request or fault report, we will immediately contact the user by phone and guide the user to solve the problem.

4. Remote connection service.

After the customer authorizes, the technical support personnel can enter the customer's system through a remote connection to help the customer solve the problem. It can be remotely connected to the customer's system to make programming adjustments on the customer's system, so as to ensure that the system produces the maximum benefit for the user.

5. On-site service.

Under the authorization of the customer, enter the customer's software management system, regularly check the system operation status, and predict the possible problems of the CNC machine in the future; if the engineer needs to understand the judgment and solve the problem on the spot, our company will arrange the engineer as soon as possible at the fastest speed rush to the scene.

6. Regularly visit customers.

After the user purchases the CNC machine, arrange after-sales engineers to visit the customer regularly (online or on-site visits). On the one hand, prevent failures, and on the other hand, respond to various problems in a timely manner. You can also ask the user Some experiences or suggestions during the process can be used as suggestions for CNC machine optimization in the future.

7. Establish a dedicated emergency response team.

To ensure that when emergencies occur, technical personnel can be called quickly, emergency technical plans are formulated immediately, and problems are solved first.

The cost of your shipment will depend on its origin, destination, value of CNC machines shipped, service, package weight, size, delivery times, and some unexpected considerations. To get the shipping cost of your CNC machine from STYLECNC, feel free to tell us.

You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we'll estimate the final price for your CNC machine.

Please note, customs fees and additional fees may apply for international shipments. Contact your local customs office for more information.

Yes, we offer paid/free ArtCAM, Type3, Mach3, Cabinet Vision, Alphacam, UcanCAM, LaserCut, CypCut, CypOne, RDWorks, EZCAD, Laser GRBL, Inkscape, EzGraver, SolveSpace, LaserWeb, LightBurn, Archicad, and more software with CNC machines purchased from STYLECNC, so it will be more convenient for you to operate the machine.

We can offer customers accessories for CNC router machines and CNC milling machines, including cutting tools (such as mills, drills, bits, and tools), tool holders, ER collets, dust collectors, as well as upgrading components such as rotary tables or automatic tool changers. We also sell accessories for CNC laser machines, such as focus lenses, rotary attachments, risers, automatic feeders, fume extractors, and water chillers. Our selection of accessories for CNC plasma cutters in stock is second to none, with everything from plasma cutting tips, torches, and nozzles to drag shields, electrodes, and air filters. Accessories for CNC wood turning lathe machines are also available for purchase online at STYLECNC, including drive centers, revolving centers, blades, chisels, tool rests, faceplates, and safety equipment such as face shields and dust masks. Additionally, you can find and buy some software for CNC programming and simulation at STYLECNC.

We helped a lot of beginners in CNC machines, if you have a basic knowledge of computers and are willing to spend a little time on learning, it is not too hard. When you ordered a CNC machine from STYLECNC, we will send the user manual and operating videos to you, you can also get the 24/7 free online service by calling, email, whatsapp, livechat or remote desktop with teamviewer.

Note: If you can't find your answer in the FAQs above, please ask a new question in the form below.

Ask Your Question

Asking questions is essential in CNC machining for fostering understanding and encouraging exploration, allowing individuals to gain deeper insights and challenge assumptions, ultimately facilitating learning and innovation.