Double Heads Stone Carving CNC Router Machine for Marble

Double heads CNC stone router machine with dual spindles will improve the working efficiency. Now the CNC stone carving machine on sale at cost price.

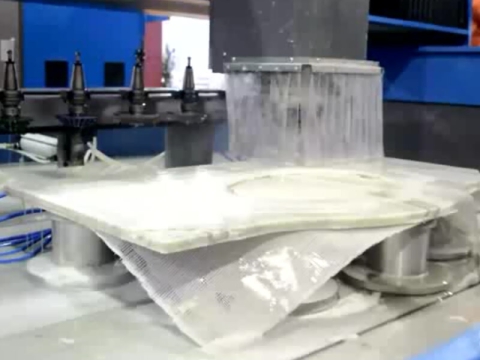

You will see how does 1325 CNC router machine with 4x8 table size carve stone, marble and granite in this video.

4x8 CNC stone router machine 1325 is designed for marble, granite, jade, bluestone, blackstone and other stone materials, as well as ceramics, glass, plexiglass, PVC board, aluminum-plastic board, bamboo and other materials.

The 1325 stone CNC router machine has completely replaced the manual work, what are the advantages of the machine tool?

1. It has a high degree of automation, which can greatly reduce the physical labor intensity of the operator.

According to the input program, the processing technology of the stone engraving machine is automatically completed. The operator only needs to start the tool setting, loading and unloading the workpiece, and changing the tool. During the stone machining process, he mainly observes and supervises the operation of the machine tool.

2. High precision and stable quality.

It has high positioning accuracy and repeat positioning accuracy. As long as the process design and program are correct, reasonable, and carefully operated, it is easier to ensure the consistency of a batch of parts, which can ensure high machining accuracy and facilitate processing. Process quality control.

3. High production efficiency.

CNC stone machining means that multiple surfaces can be processed again during the processing process. Generally, only the first surface is detected. Therefore, when processing ordinary stone carving machines, many intermediate processes can be omitted, such as marking and dimensional testing, which reduces auxiliary time. In addition, due to the stable quality of CNC-machined parts, it brings convenience to subsequent processes and significantly improves overall efficiency.

4. Facilitate the development and transformation of new products

CNC machining generally does not require a lot of complicated process equipment. Stones with complex shapes and high precision requirements can be processed by programming the machining program. When the product is changed and the design is changed, as long as the program is changed, there is no need to redesign the tool, so CNC stone machining can greatly shorten the product development cycle.

Double heads CNC stone router machine with dual spindles will improve the working efficiency. Now the CNC stone carving machine on sale at cost price.

Mini stone CNC router STS6090 with 2.2KW water-cooling spindle and water tank, so as to carve on granite, marble, sandstone, limestone, and artificial stone.

You will see how does an ATC CNC stone cutting machine cut hand washing sink with automatic tool changer in this video.