MOPA & Q-Switched Fiber Laser

MOPA is the acronym for Master Oscillator Power Amplifier. MOPA laser refers to a laser structure in which a laser oscillator and an amplifier are cascaded. In the industrial world, MOPA laser refers to a unique, more "intelligent" nanosecond pulsed fiber laser composed of a semiconductor laser seed source and a fiber amplifier driven by electrical pulses.

Its "intelligence" is mainly reflected in the independently adjustable output pulse width (ranging from 2 ns to 500 ns), and the repetition frequency can be as high as megahertz. The seed source structure of the Q-switched fiber laser is to insert a loss modulator in the fiber oscillating cavity, which generates a nanosecond pulse light output with a certain pulse width by periodically modulating the optical loss in the cavity.

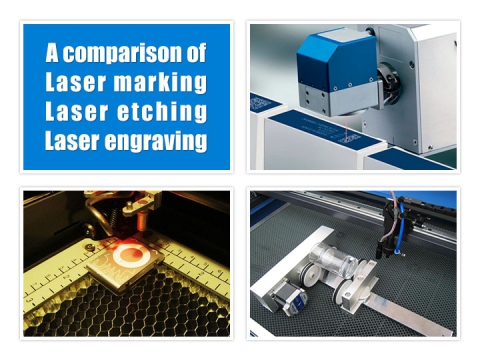

Nanosecond pulsed lasers are well known for industrial applications such as metal marking, welding, cleaning, and cutting. As the two major implementations of nanosecond pulsed lasers, what are the differences and advantages of MOPA structure and Q-switched structure? For this problem that often troubles everyone, we will make a simple analysis from the internal structure of the laser, output optical parameters and application scenarios.

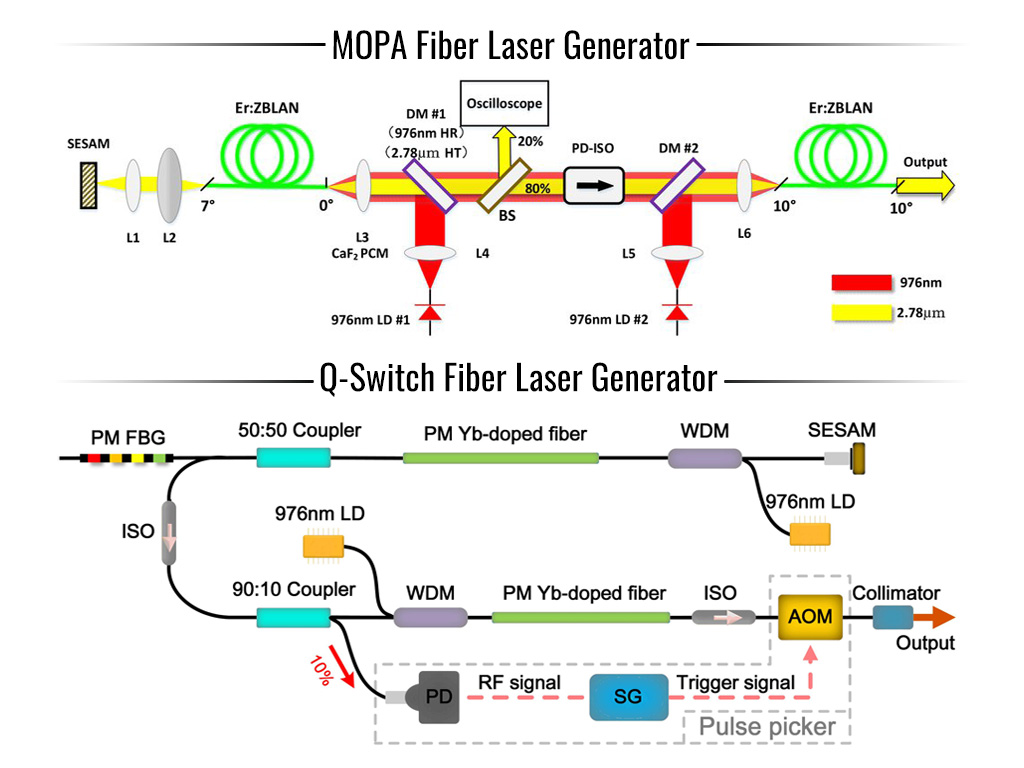

Internal Structure Comparison

Comparison of internal structure and principle of MOPA fiber laser generator and Q-switched fiber laser generator.

The internal structure difference between MOPA fiber laser and Q-switched fiber laser is mainly in the way of generating the pulse seed optical signal.

The MOPA fiber laser pulse seed optical signal is generated by the electric pulse driving the semiconductor laser chip, that is, the output optical signal is modulated by driving the electric signal, so it has a strong ability to generate different pulse parameters (pulse width, repetition frequency, pulse shape and power).

The pulsed seed optical signal of the Q-switched fiber laser generates pulsed light output by periodically increasing or decreasing the optical loss in the resonator, and has a simple structure and a price advantage. However, due to the influence of Q-switched devices, the pulse parameters are limited.

Optical Parameters Comparison

The output pulse width of the MOPA fiber laser is independently adjustable. The pulse width of MOPA fiber lasers is arbitrarily tunable (ranging from 2 ns to 500 ns). The narrower the pulse width, the smaller the heat-affected area, and the higher the machining accuracy can be obtained. The output pulse width of the Q-switched fiber laser is not adjustable, and the output pulse width is generally unchanged at a fixed value of 80 ns to 140 ns.

MOPA fiber lasers have a wider repetition frequency range. MOPA laser repetition frequency can reach the high frequency output of MHz. High repetition frequency means high processing efficiency, and MOPA can still maintain high peak power characteristics under high repetition frequency conditions. Due to the limitation of the working conditions of the Q-switch, the Q-switched fiber laser has a narrow output frequency range, and the high frequency can only reach ~100 kHz.

Applications Comparison

The application differences between MOPA laser marking machine and Q-Switch laser marking machine.

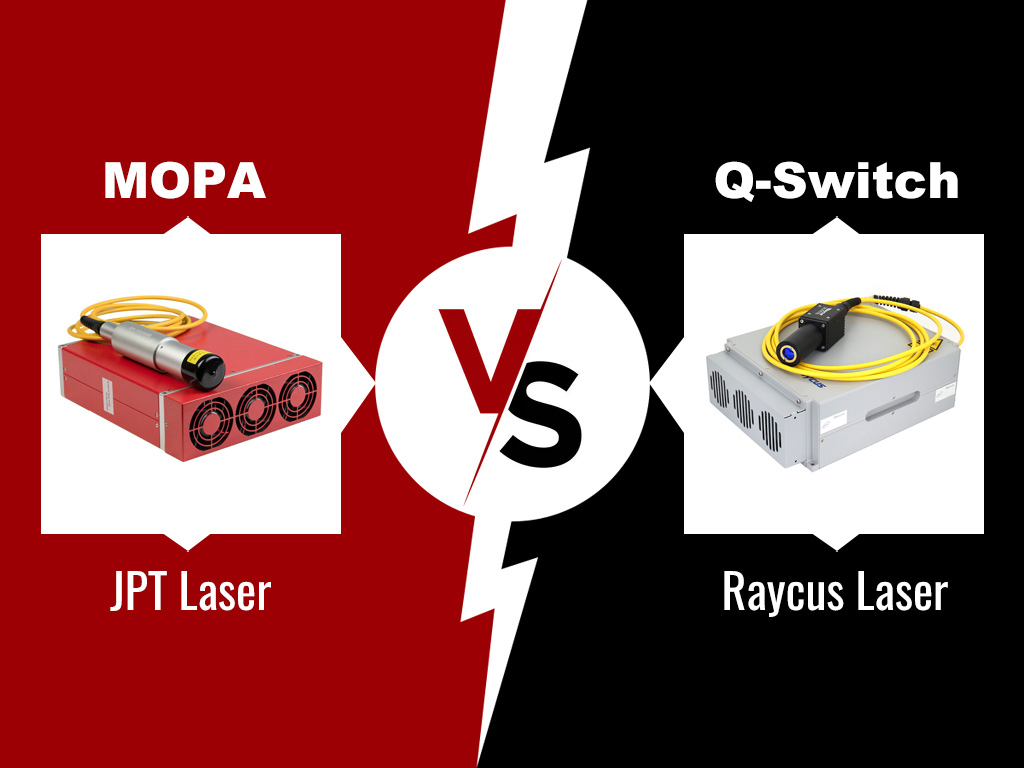

JPT MOPA Fiber Laser Generator

Raycus Q-Switched Fiber Laser Generator

Alumine Sheet Stripped Surface Applications

Now, more and more thin electronic products, many mobile phones, tablets, computers are using a thin aluminum oxide as the product of the shell. Using laser Q-switch in thin aluminum plate marking guide potential, easily lead to deformation of the material, abaxially produced "convex hull", directly affect the appearance. The parameters of MOPA laser pulse width smaller, which can make the material easy to deformation, shading is more delicate and bright white. This is due to the laser MOPA use the pulse width parameter can make laser stay at the material time becomes shorter, and sufficiently high energy can remove the anode layer, so for thin aluminum plate surface stripping anode processing, MOPA laser is a better choice.

Anodic Alumina's Black Marking Applications

The use of laser in the anodic alumina surface marking a black mark, model and text, the application in the recent two years is gradually Apple, Huawei, Lenovo, Samsung electronic manufacturers widely used for electronic product shell, used for marking black mark on the trade marks, models, etc.. For this type of applications, there are only MOPA laser can be processed. Because has a wide pulse width and pulse frequency adjustment range of the laser MOPA by narrow pulse width and high frequency parameters can be on the material surface marked effect of black, through different combinations of parameters can also play marked the effect of different gray.

Electronic, Semiconductor, ITO Precision Machining Applications

In the electronics, semiconductor, and ITO and other precision machining, mainly need to use fine line marking. because of Q-switch laser structure, it can not adjust the pulse width parameters, so the line is difficult to achieve fine. The MOPA laser can be flexible to adjust the pulse width and frequency parameters, which can not only make the line fine, but also the edge is not smooth.

In addition to the above several application cases, there are many different applications of MOPA laser and Q-switch laser, here are some typical examples of applications with the following table:

| Applications | Q-Switched Laser Marking System | MOPA Laser Marking System |

| Alumine Sheet Stripped Surface | Easy Seformation, Rough Marking | No Deformation, Fine Marking |

| Alumine Sheet Black Color Marking | Disable. | Marking Different Black Colors by Setting the Parameters. |

| Metal Depth Marking. | Rough Marking. | Fine Marking. |

| Stainless Steel Color Marking. | Difficult to Set Parameters, and Out of Focus. | Marking Different Colors by Setting The Parameters. |

| PC, ABS Plastic. | Rough Marking with Yello Edge. | Smooth without Yellow Edge. |

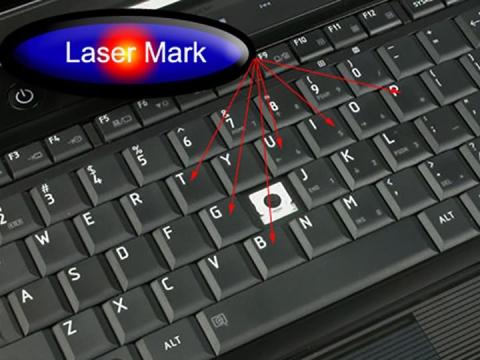

| Light Transmission Paint Keyboard. | Disable. | Easy to Make it Pervious to Light. |

| Electronic, Semiconductor Components, ITO Precision Machining. | Higher Pulse Width and Power. | The Pulse can be Adjusted to Get The Best Facula, and Make The Power Balance. |

In the comparison of the above introduction, we can see that the MOPA fiber laser marking machines can replace the Q-switched fiber laser engravers in many applications. In some of the more high-end applications, MOPA fiber laser engraver is better than the Q-switched fiber laser marking system.

Technical Parameters Comparison

MOPA and Q-Switch Laser Marking Machine Technical Parameter Similarities & Differences

| Model | STJ-30F | STJ-30FM |

| Laser Power | 30W | 30W |

| Laser Source | Raycus Q-Switched Fiber Laser | JPT MOPA Fiber Laser |

| Impulse Width | 90-120ns | 6-250ns |

| Power Adjustable Range | 10-100% | 0-100% |

| Pulse Energy | 1Mj | 0.5mj |

| M2 | <1.5 | <1.3 |

| Resist High-Reflection | NO | YES |

| Laser Beam Diameter | 7±1mm | 7±0.5mm |

| Light Wavelength | 1064nm | |

| Laser Modulation Mode | Coupling Amplification | |

| Marking Area | 100*100mm (200*200mm and 300*300mm for option) | |

| Max Marking Speed | 7000mm/s | |

| Marking Depth | 0.01~0.5mm (Based on the Materials) | |

| Min Linewidth | 0.01mm | |

| Min Marking Character | 0.2mm | |

| Cooling Method | Air Cooling | |

| Power Supply | 220V/50Hz | |

| Laser Indicator | Red Dot Pointer | |

| Marking Content | Text, Pattern, Photo | |

| Operation System | Windows 7 or Windows 8 or Windows 10 | |

| Laser Software | EZCAD Control Software | |

| Graphic Formats Supported | bmp, jpg, gif, tga, png, tif, ai, dxf, dst, plt | |

| Unit Power | ≤700W | |

Learn More About Different Fiber Laser Marking Machines

|  |

| MOPA Fiber Laser Marking Machine | Q-Switch Fiber Laser Marking Machine |

Summary

In a word, MOPA fiber laser has wider laser parameter coverage, more flexible adjustment and more comprehensive application range than Q-switched fiber laser. In the case of the same power, Q-switched fiber lasers have more cost advantages. Therefore, these two laser structures present a complementary state in the application market of nanosecond pulsed laser processing.