Global CNC Machining Prospects & Outlook In 2024

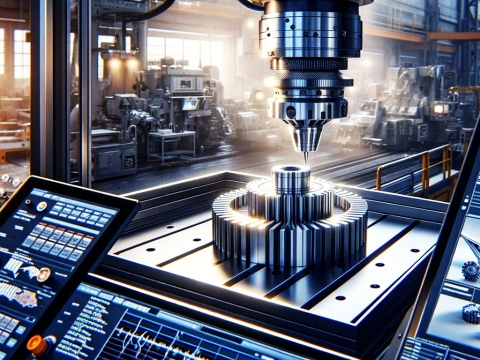

CNC technology not only brings revolutionary changes to traditional manufacturing and makes manufacturing a symbol of industrialization, but also plays an important role in the development of some important industries of the national economy with the continuous development of CNC processing technology and the expansion of application fields. people's livelihood. A more important role. Although the trend of high precision and high speed has emerged more than ten years ago, the development of science and technology is never-ending. The meaning of high precision and high speed is constantly changing and is developing towards the limits of precision and speed.

Let's look at the global trends of CNC machining technology in 2024 from the following aspects:

1. Development of high-speed, precise, intelligent and miniaturized machine tools.

With the widespread application of light alloy materials in industries such as automobiles and aerospace, high-speed processing has become an important development trend in manufacturing technology. High-speed machining has the advantages of shortening processing time, improving processing accuracy and surface quality, and is increasingly used in fields such as mold manufacturing. The high speed of machine tools requires new CNC systems, high-speed electric spindles and high-speed servo feed drives, as well as optimization and lightweighting of machine tool structures. High-speed machining is not only the equipment itself, but also the combination of machine tools, cutting tools, tool holders, fixtures, CNC programming technology and personnel quality. The ultimate goal of high speed is to improve efficiency. Machine tools are just one of the keys to achieving high efficiency. This is by no means all. Production efficiency and effectiveness are at the "tip of the knife".

2. Five-axis linkage processing and compound processing machine tools are developing rapidly.

Using five-axis linkage to process three-dimensional curved surface parts, the optimal geometry of the tool can be used for cutting, which not only provides a high finish, but also greatly improves efficiency. It is generally believed that the efficiency of a five-axis linkage machine tool can be equivalent to that of two three-axis linkage machine tools. Especially when using super-hard material tools such as cubic boron nitride to mill quenched steel parts at high speed, the efficiency of a five-axis linkage machine tool can be equal to that of two three-axis linkage machine tools. Taiwan three-axis linkage machine tool is equivalent. Three-axis simultaneous machining is more effective than three-axis simultaneous machining. However, in the past, due to the complex host structure of the five-axis linkage CNC system, its price was several times higher than that of three-axis linkage CNC machine tools, and the programming technology was more difficult, which restricted the development of five-axis linkage machine tools. The current development of CNC machining technology has greatly simplified the structure of the five-axis linkage machining composite spindle head, greatly reduced the manufacturing difficulty and cost, and narrowed the price gap of CNC systems. Therefore, five-axis linkage technology promotes the development of composite spindle head type five-axis linkage machine tools and compound processing machine tools.

3. The development of new structures, new materials and new design methods.

The high speed and high precision of machine tools require the simplification and lightweight of machine tool structures to reduce the negative impact of the inertia of machine tool components on machining accuracy and greatly improve the dynamic performance of machine tools. For example, the topology optimization of machine tool components with the help of finite element analysis, the design of box-in-box structures, the use of hollow welding structures, the use of lead alloy materials, etc. have begun to move from the laboratory to industrialization. actual use.

CNC machine design and development should transition from 2D CAD to 3D CAD as soon as possible. Three-dimensional modeling and simulation are the foundation of modern design and the source of corporate technological advantages. Based on this three-dimensional design, CAD/CAM/CAE/PDM integration is carried out to speed up the development of new products, ensure the smooth launch of new products, and gradually realize product life cycle management.

4. The development of open CNC systems.

Many countries have conducted research on open CNC systems, and the opening of CNC systems has become the future. The so-called open CNC system is that the development of the CNC system can be oriented to machine tool manufacturers and end users on a unified operating platform, by changing, adding or cutting structural objects (CNC function), to form a series, and can easily Special applications and technical know-how are integrated into the control system to quickly realize open CNC systems of different varieties and grades, forming famous brand products with distinctive personalities. There are three forms of open CNC systems:

A. Fully open system, that is, a microcomputer-based numerical control system, using a microcomputer as a platform, using a real-time operating system, developing various functions of the numerical control system, transmitting data through a servo card, and controlling the movement of a coordinate axis motor.

B. Embedded system, namely CNC + PC, CNC controls the movement of the coordinate axis motor, PC as a man-machine interface and network communication.

C. Fusion system, add PC motherboard on the basis of CNC, provide keyboard operation, improve the man-machine interface function.

The architecture specification, communication specification, configuration specification, operating platform, CNC system function library and software development tools of the open CNC system are the core of the current research.

5. Development of reconfigurable manufacturing systems.

As the speed of product upgrades accelerates, the reconfigurability of special machine tools and the reorganizability of manufacturing systems are increasingly important. Through the modularization of CNC machining units and functional components, the manufacturing system can be quickly reorganized and configured to meet the production needs of modified products. The interface standardization and standardization of mechanical, electrical and electronic, liquid and gas, and control software is the key to achieve reorganization.

6. Development of virtual machine tools and virtual manufacturing.

In order to speed up the development speed and quality of new machine tools, with the help of virtual reality technology in the design stage, you can evaluate the correctness and performance of machine tool design before the machine tool is manufactured, and find various errors in the design process at an early stage to reduce Loss, improve the quality of new machine tool development.